About Graphic Medium

Industrial Engineering Consulting Built on Real Plant Experience

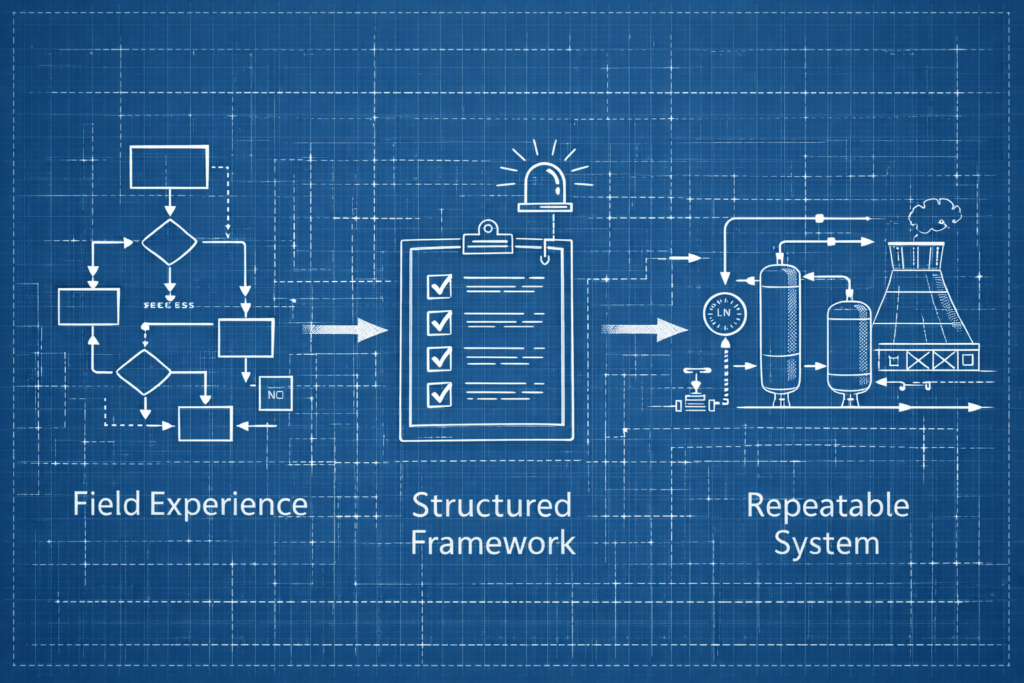

Graphic Medium is an industrial engineering consulting and knowledge platform built to support real-world plant operations — not academic discussions or generic frameworks.

Our work is grounded in commissioning and operations experience across cryogenic nitrogen plants and ASU systems. We focus on commissioning clarity, operational stability, troubleshooting discipline, and documentation that reflects how plants actually behave.

We don’t promote abstract models or generic frameworks.

We capture, structure, and apply engineering experience from the field.

At Graphic Medium, our industrial engineering consulting approach is delivered through selective, scope-defined industrial consulting services built on real plant experience.

Who We Are

Graphic Medium was established to address a persistent gap in industrial engineering consulting:

Strong field experience that remains undocumented

Detailed procedures that lack operational clarity

Plant teams forced to rely on trial-and-error during critical commissioning and troubleshooting phases.

We exist to bridge these gaps by converting experience-based engineering insight into structured, usable systems that engineers can depend on — during commissioning, troubleshooting, audits, and daily operations.

Our work sits at the intersection of:

Field execution

Engineering judgment

Structured documentation

This is where effective industrial engineering consulting delivers real value.

We also publish engineering insights and field guides to document recurring plant patterns, stability issues, and commissioning lessons.

What We Do

Industrial Engineering Consulting (Selective)

We provide industrial engineering consulting for complex, high-impact plant phases where clarity and structure matter most:

Cryogenic nitrogen plant commissioning

ASU start-up and stabilization

Operational troubleshooting and root cause analysis

Safety, interlock, and SOP documentation alignment

Our consulting engagements are scope-defined, documentation-backed, and tool-supported — ensuring outcomes remain useful long after the engagement ends.

Digital Engineering Knowledge Systems

Alongside consulting, we develop digital engineering resources that support and extend our industrial engineering consulting work, including:

Engineering micro-books

Each resource is designed for real plant use — printable, structured, and practical for control rooms and site teams.

We do not replace engineering teams.

We strengthen them with structure, logic, and proven methods.

Our Approach to Industrial Engineering Consulting

We work differently from generic industrial consultants.

Field-Experience Driven

Grounded in Real Commissioning and Operations

Structured Frameworks

Not Verbal Advice or Slide Decks

Documentation-Backed

Clear, Traceable, Reusable Outputs

Selective Engagement

Depth and Quality Over Volume

Our approach ensures that industrial engineering consulting results in lasting capability, not temporary fixes.

Our industrial engineering consulting approach respects recognized engineering standards published by ASME for industrial and pressure systems.

Who We Work With

Our industrial engineering consulting supports:

Commissioning Engineers

Operations and Maintenance Teams

EPC and Project Engineers

Plant Managers and Technical Leadership

Across cryogenic nitrogen plants and industrial gas facilities.

Our Mission

Our mission is to improve industrial performance by delivering industrial engineering consulting that converts field experience into structured, repeatable systems.

We aim to:

Reduce uncertainty during commissioning and troubleshooting

Improve operational stability through understanding, not guesswork

Enable safer plants through clear procedures and documentation

Preserve engineering intent by capturing knowledge before it is lost

We believe engineering knowledge should be accessible, reliable, and reusable — not dependent on individuals alone.

Our Values

Field Reality First

We value what works on live plants over what looks good on paper.

Structure Creates Clarity

Well-structured systems lead to better decisions and safer outcomes.

Documentation Is an Engineering Tool

Documentation is not paperwork — it is a core operational asset.

Independence Over Dependency

Good industrial engineering consulting leaves teams more capable, not reliant.

Safety Is Non-Negotiable

Every recommendation must protect people, equipment, and process integrity.

Why Graphic Medium

Engineering-First Mindset

Decisions driven by engineering logic, not marketing narratives.

No Generic Training or Academic Theory

No recycled slides or classroom models — only field-tested insight.

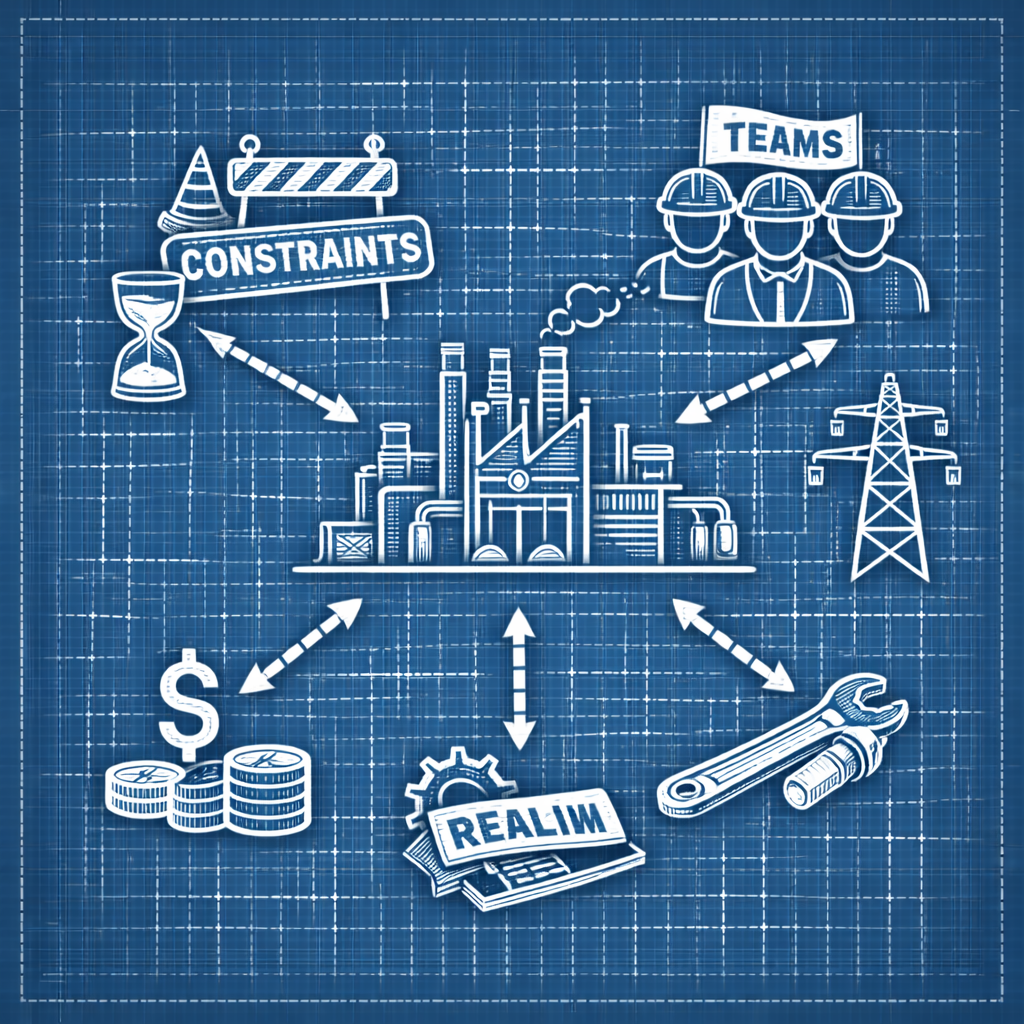

Built for Real Plants, Real Constraints, Real Teams

Designed for operating plants, limited time, and real-world limitations.

Consulting Supported by Practical Tools

Every engagement produces usable checklists, logs, and frameworks.

If you’re looking for industrial engineering consulting grounded in field experience and structured thinking, Graphic Medium is built specifically for that purpose.

Let’s Solve Real Plant Problems — Systematically

Whether you’re commissioning a new unit, stabilizing an operating plant, or tightening safety and documentation practices, industrial engineering consulting backed by real, field-tested tools can save weeks of trial and error.

At Graphic Medium, we support engineering teams with field-tested frameworks, structured documentation, and practical guidance designed for real industrial conditions — not presentations or theory.

Discuss a specific commissioning, troubleshooting, or documentation challenge with a scope-defined, engineering-first approach.

Access ready-to-use checklists, diagnostic worksheets, and stabilization tools built from real plant experience.