Cryogenic Nitrogen Plant Stability Toolkit

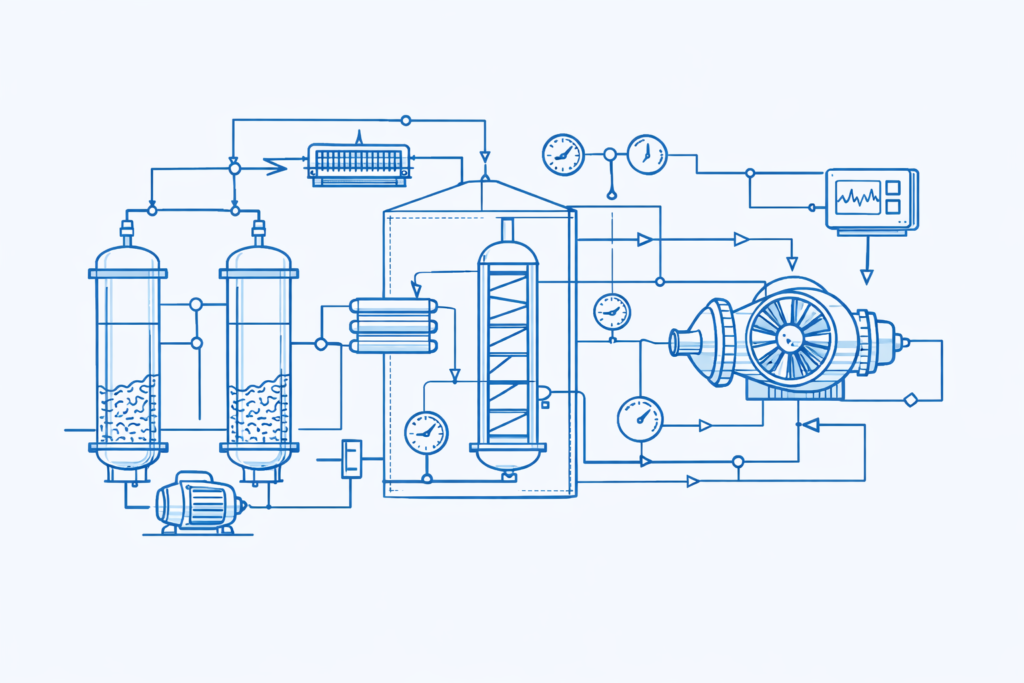

The Cryogenic Nitrogen Plant Stability Toolkit is a structured field documentation and guidance system designed to support plant stability during commissioning, start-up, and early operation of cryogenic nitrogen plants.

This toolkit is designed for engineering teams managing the highest-risk phase of plant life — where small oversights, sequencing errors, and undocumented assumptions can lead to trips, contamination, or long-term instability.

Instant digital download.

Use during commissioning, operations, or audits.

Why Cryogenic Nitrogen Plant Stability Toolkit matters

These are not design failures — they are commissioning and early-operation gaps.

The Cryogenic Nitrogen Plant Stability Toolkit addresses the most common failures observed during commissioning and early operation — where small sequencing errors, missed interlocks, or undocumented assumptions can escalate into purity loss, icing, or repeated trips.

In cryogenic nitrogen plants, commissioning and early operation failures addressed by the Cryogenic Nitrogen Plant Stability Toolkit rarely come from missing equipment.

They typically arise from:

Incomplete safety and interlock verification

Poor sequencing during cold box cool-down

Hidden contamination (moisture, CO₂, air ingress)

Expander instability and control loop hunting

Weak documentation during handover to operations

By the time alarms activate, the root cause has often existed quietly for hours or days.

The Cryogenic Nitrogen Plant Stability Toolkit provides structured field guidance and documentation to help engineering teams:

Reduce start-up and stabilization risk

Detect early instability patterns

Avoid unnecessary tuning or corrective action

Maintain clarity across teams, shifts, and handovers

This toolkit supports engineering judgment. It does not replace OEM manuals or site-specific procedures.

For teams focused on pre-start checks and first cool-down, the Commissioning Toolkit supports earlier phases, while the Troubleshooting Toolkit is better suited for diagnosing steady-state operating problems.

Commissioning & Stability Lifecycle Covered by This Toolkit

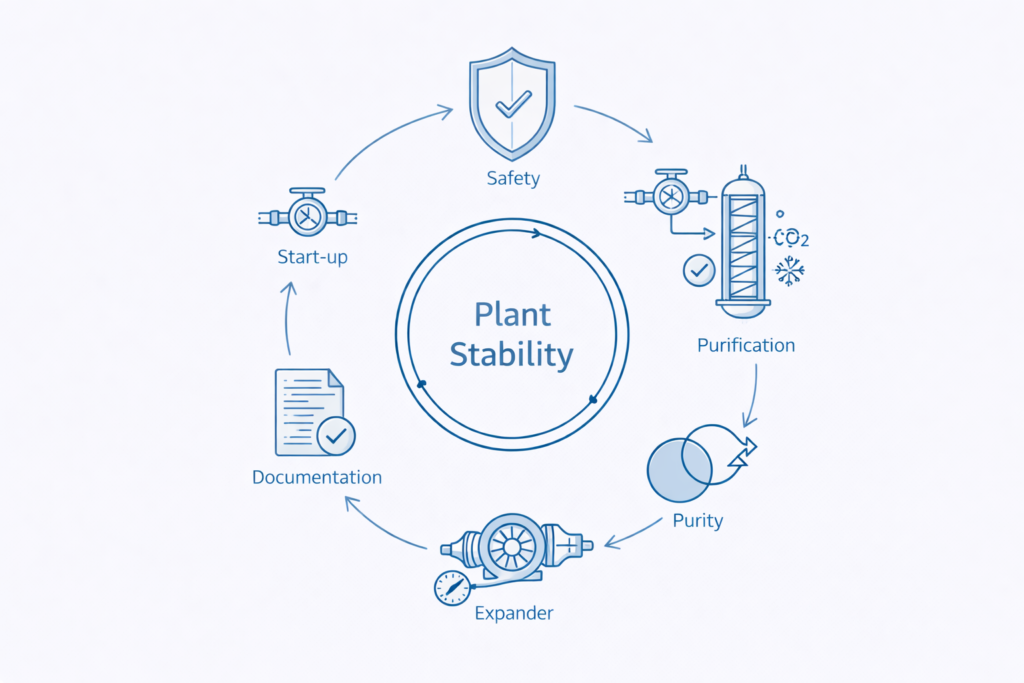

The Cryogenic Nitrogen Plant Stability Toolkit follows the actual lifecycle of a nitrogen plant — from safety readiness and controlled cool-down to stabilization, diagnosis, and recovery.

The toolkit is structured around the actual lifecycle of a nitrogen plant, not theoretical commissioning steps.

It supports the following phases:

Pre-start safety and interlock readiness

Cold box cool-down and thermal stabilization

Purification and contamination control

Expander behavior and control loop stability

Early purity recovery and trend interpretation

Deviation tracking and technical handover

Used together, these guides form a repeatable commissioning and stabilization workflow.

What’s included in Cryogenic Nitrogen Plant Stability Toolkit

The Cryogenic Nitrogen Plant Stability Toolkit includes six focused engineering guides covering safety, start-up, purification, expander stability, air ingress, and nitrogen purity recovery.

Purity Stability Framework

Explains how purity responds to load changes, flow balance, and column behavior to help maintain steady product quality.

Trend Reading Pattern Guide

Helps interpret DCS trends to distinguish normal process shifts from early signs of instability.

Cold Box Flooding

Guide

Step-by-step guide to detect, analyze, and recover from liquid accumulation inside the cold box that leads to purity loss and startup failures.

Cold Box Temperature Mapping Sheet

Maps expected temperature profiles to identify flooding, maldistribution, or heat exchanger imbalance.

Pressure & Temperature Differential Diagnosis Sheet

Uses ΔP and ΔT trends to detect developing restrictions and internal imbalance.

Pressure Stability Diagnostic Sheet

A quick-reference worksheet to identify pressure fluctuations, control loop issues, and system imbalances causing unstable plant operation.

Together, these guides form a single, integrated Cryogenic Nitrogen Plant Stability Toolkit rather than isolated documents.

Each guide is designed to be used independently or as part of the full commissioning and stability workflow.

Individual technical topics covered in this toolkit are also available in the Industrial Cryogenic Micro-Books Library.

How these guides work together

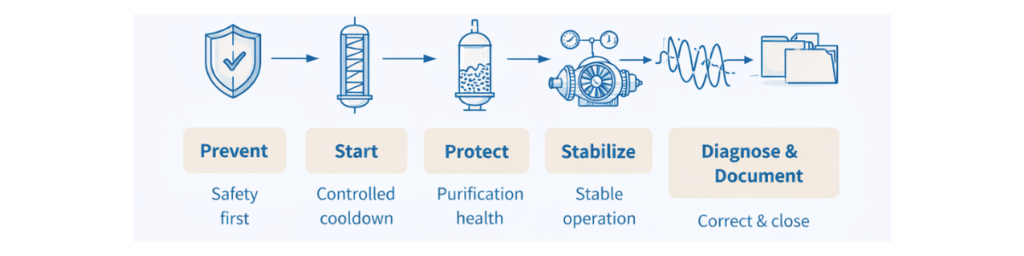

The Cryogenic Nitrogen Plant Stability Toolkit follows a system logic rather than isolated troubleshooting, ensuring stability is maintained across commissioning and early operation.

Prevent → Start → Protect → Stabilize → Diagnose → Recover

Safety and interlocks prevent unsafe start conditions

Start-up guidance controls thermal and flow transitions

Purification and air ingress guidance protect the cold box

Expander stability prevents cascading trips

Purity troubleshooting supports stable production

This integrated approach helps teams avoid repeat failures across projects.

Who this Cryogenic Nitrogen Plant Stability Toolkit is for

The Cryogenic Nitrogen Plant Stability Toolkit is designed for engineering teams responsible for plant safety, controlled start-up, and long-term operational stability.

Commissioning Engineers

Lead pre-start checks, system validation, and safe handover from construction to operations.

Start-up Engineers

Execute cold box cool-down, flow sequencing, and early stabilization during first plant runs.

Plant Managers

Maintain production stability, safety compliance, and rapid recovery from upsets or purity loss.

EPC and OEM Support Teams

Support multiple sites with standardized diagnostics, commissioning logic, and issue verification.

Operations Leads

Monitor daily plant behavior, manage deviations, and prevent small issues from escalating.

Reliability / Process Engineer

Analyze trends, root causes, and recurring failures to improve long-term plant stability.

For teams focused primarily on pre-start checks and first cool-down, see the Cryogenic Nitrogen plant Commissioning Toolkit.

Teams requiring structured audit and incident documentation can use this toolkit alongside the Cryogenic Nitrogen Plant Safety Documentation.

For steady-state operation issues and live plant fault diagnosis, this toolkit pairs well with the Cryogenic Nitrogen Plant Troubleshooting Toolkit.

How this cryogenic nitrogen plant Stability Toolkit fits with other toolkits

The Cryogenic Nitrogen plant Stability Toolkit can be used independently or alongside:

Safety & Compliance Pack

Focused on safety verification, incident documentation, and audit readiness.

Commissioning & Stability Toolkit

Provides structured field guidance and documentation to help engineering teams.

Troubleshooting Toolkit

Focused on diagnosing issues during steady-state operation.

This toolkit focuses on commissioning and early stability; troubleshooting packs are optimized for steady-state and upset recovery.

👉 Get the Stability Toolkit

₹ 499

Instant Digital Download • Lifetime Free Updates

Used during commissioning, start-up, and live operation troubleshooting

🛡 100% Engineer-Friendly. No fluff.

Optional Add-ons

✔ Remote consulting

✔ Document review

Discount when purchased

Discount when purchased

with Commissioning /

Troubleshooting Pack

Available separately. Not

Available separately. Not

required to use the toolkit.

The Cryogenic Nitrogen Plant Stability Toolkit can be used independently or alongside your existing commissioning, troubleshooting, or safety documentation.

Startup Success Bundle

Most commissioning teams also use safety and stability documentation during startup.

Includes:

Commissioning Toolkit

Safety Toolkit

Stability Toolkit

₹1,499

Important note

This cryogenic nitrogen plant safety documentation provides general guidance and documentation structure only.

Always follow:

Site-specific safety procedures

OEM manuals

Statutory and regulatory requirements

Always follow applicable statutory requirements and recognized safety standards, such as guidance issued by relevant regulatory authorities.

Disclaimer

This material is provided for general guidance and documentation support only.

Actual plant design, safety requirements, and operating procedures vary by site and manufacturer.

Always follow approved site procedures, OEM manuals, and applicable safety regulations.

The author assumes no responsibility for plant performance, safety incidents, or compliance outcomes arising from the use of this material.