Cryogenic Toolkit Bundles

Individual Toolkits

Troubleshooting Toolkit

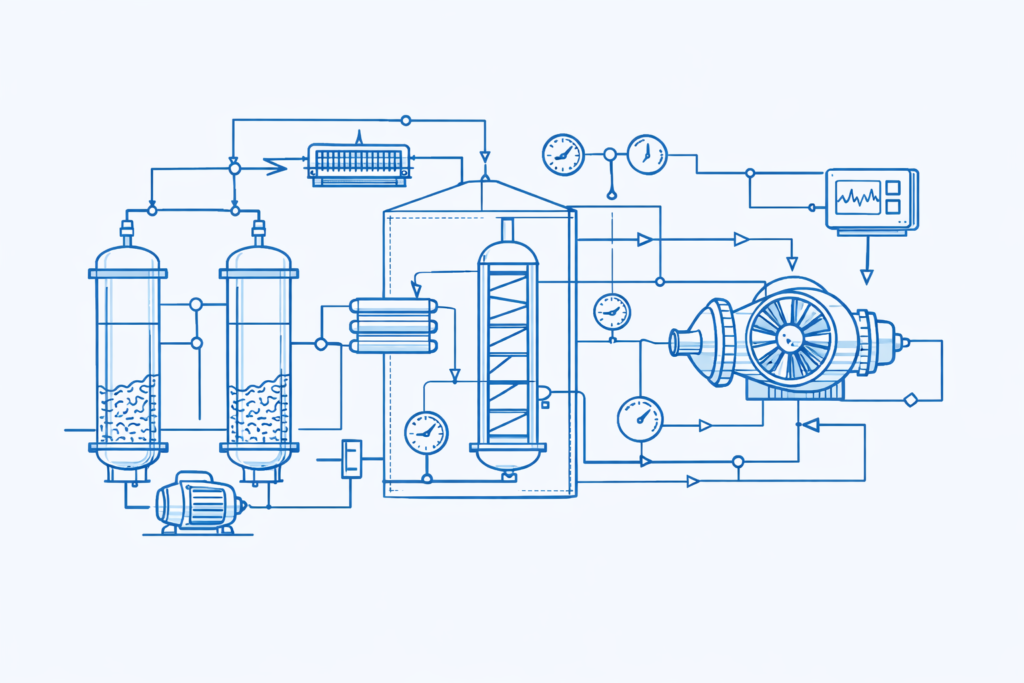

• Diagnose purity, pressure, cold box issues

• Field-tested RCA & recovery tools

Commissioning Toolkit

• Structured startup & handover system

• Pre-checks, cold box start-up, interlocks

Stability

Toolkit

• Purity Stability & Process Control

• Purity drift, Load change behavior, Column imbalance

Safety & Compliance Pack

• Structured safety documentation. • Safety, Interlocks, and Compliance, Cause & Effect.

Cryogenic Nitrogen Plant Toolkit Bundles

These bundled toolkits are designed for teams who want a complete commissioning, troubleshooting, and safety workflow — with cost savings compared to buying tools separately.

1. Start-Up & Stabilization Bundle

Includes:

✅ Commissioning Toolkit

✅ Stability Toolkit

Best for:

Commissioning teams, EPC handover phase, new plant startups

Problem it solves:

From first purge → cool-down → stable purity

2. Operations Reliability Bundle

Includes:

✅ Stability Toolkit

✅ Troubleshooting Toolkit

Best for:

Running plants, reliability engineers, shift leads

Problem it solves:

Trip reduction, purity drops, recurring disturbances

3. Safety & Audit Readiness Bundle

Includes:

✅ Safety & Compliance Pack

✅ Commissioning Toolkit

Best for:

EPCs, safety officers, audit preparation

Problem it solves:

Interlock verification + traceable documentation

4. Complete Cryogenic Plant Toolkit

Includes:

✅ Commissioning Toolkit

✅ Stability Toolkit

✅ Troubleshooting Toolkit

✅ Safety & Compliance Pack

Best for:

Multi-site operators, consultants, OEM support teams

Problem it solves:

Full lifecycle coverage — startup to operations to audits

Disclaimer

These digital products are provided for educational training and general engineering reference only.

They do not replace OEM manuals, plant-specific operating procedures, safety regulations, or qualified engineering supervision.

All values, examples, and sequences shown are typical reference practices and may vary by plant design, OEM, operating conditions, and regulatory requirements.

Users must verify all parameters and procedures with OEM documentation and site-approved instructions before application.

Execution of any operational steps must be performed only by trained and authorized personnel following applicable safety rules.

Graphic Medium Industrial Consulting disclaims any liability for loss, damage, or injury arising from the use or interpretation of this material.