Top 10 Common Nitrogen Plant Start up Problems

( and How to Fix Them)

Learn how to identify, prevent, and fix the most common nitrogen plant start up problems — based on real commissioning experience.

Successful commissioning and start-up depend on preparation and structured testing. Before you begin, download our Cryogenic Nitrogen Plant Commissioning Checklist (PDF) — it’s designed to help you verify every system, from air compression to product delivery.

Introduction

Starting up a cryogenic nitrogen plant is one of the most critical and sensitive stages of the entire project lifecycle. Every valve, sensor, and heat exchanger must operate precisely as designed to ensure stable production and product purity.

However, nitrogen plant start up problems are common — especially when the commissioning process is rushed or incomplete. These issues can delay production, affect purity, or even cause safety risks if not addressed methodically.

At Graphic Medium Industrial, we’ve seen these challenges frequently across a wide range of commissioning scenarios. This post outlines the 10 most common nitrogen plant start up problems and shares practical, industry-informed solutions to help engineers address them systematically.

Many nitrogen plant start up problems arise from improper system balance, instrumentation discrepancies, or insufficient drying cycles.

In our experience, most nitrogen plant start-up problems are not isolated failures — they are symptoms of incomplete system verification, missing documentation, or rushed commissioning. This guide highlights common issues and shows how structured preparation prevents them.

This guide explains the most common nitrogen plant start up problems, why they occur, and the exact field fixes engineers use during commissioning and stabilization.

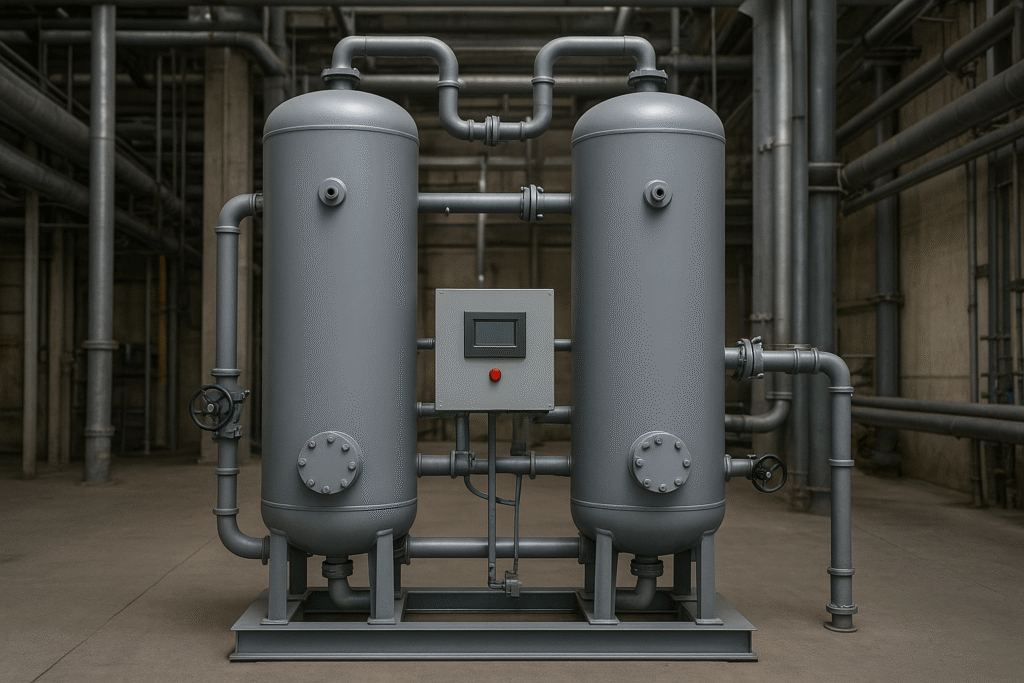

1️⃣ Incomplete System Drying – A Common Nitrogen Plant Start Up Problem

Problem:

Pretreatment failure is the most critical cause of nitrogen plant start up problems. If molecular sieve beds fail to remove moisture and CO₂ effectively, contaminants enter the cold box and freeze immediately.

Impact:

• Ice formation in exchangers

• CO₂ solid blockage

• Rising pressure drop

• Reduced nitrogen purity

• Sudden startup trips

Fix:

Verify dew point and CO₂ levels before cooldown. Confirm proper regeneration temperature, purge flow, and cycle time. Never start the cold box if pretreatment performance is unstable.

2️⃣ Improper Insulation or Vacuum Leaks

Problem:

Loss of insulation integrity or vacuum leakage allows heat ingress into the cold section. This increases cold box temperatures and creates unstable refrigeration — a major cause of nitrogen plant start up problems.

Impact:

• Poor separation efficiency

• Higher refrigeration load

• Excess compressor power

• Delayed stabilization

Fix:

Verify vacuum integrity before startup. Inspect joints, flanges, and multilayer insulation. Use helium leak testing or pressure decay methods to detect hidden leaks.

Incorrect Valve Line-Up -

Incorrect Valve Line-Up -

Problem:

Even a single misaligned valve can disrupt flow balance or pressure profiles. Incorrect valve positions frequently cause unexpected nitrogen plant start up problems during commissioning.

Impact:

• No flow to exchangers

• Column instability

• Blocked process paths

• Sudden pressure spikes

• Failed startup sequences

Fix:

Follow a documented valve line-up checklist. Tag critical valves and cross-verify with P&ID before startup. Conduct a final walk-down during commissioning.

4️⃣ Instrumentation Calibration Errors Causing Nitrogen Plant Start Up Problems

Problem:

Uncalibrated transmitters, reversed wiring, or faulty signals produce misleading readings. Operators then make incorrect adjustments, creating unnecessary nitrogen plant start up problems.

Impact:

• False alarms

• Incorrect control actions

• Process instability

• Startup delays

Fix:

Perform complete loop checks for temperature, pressure, and flow instruments. Validate alarm setpoints and interlock logic through DCS simulation before live startup.

“For broader instrumentation guidance, refer to resources published by organizations such as the International Society of Automation (ISA)

5️⃣ Oil or Moisture Carryover from Compressors – One of the Most Overlooked Nitrogen Plant Start Up Problems

Problem:

Compressor oil or moisture contamination damages adsorbent beds and blocks filters. This hidden issue often causes recurring nitrogen plant start up problems after maintenance or restart.

Impact:

• Adsorber fouling

• Reduced pretreatment efficiency

• Cold box contamination

• Frequent breakdowns

Fix:

Replace filters and separators regularly. Drain moisture traps. Verify oil carryover limits and ensure compressors start with clean, dry air systems.

Many start-up problems stem from missed checks. Download the Cryogenic Nitrogen Plant Commissioning Checklist (PDF).

The Cryogenic Nitrogen Plant Troubleshooting Toolkit includes startup logs, stability sheets, pretreatment checks, and failure diagnostics

6️⃣ Refrigeration System Instability

Problem:

Poor balance in the refrigeration cycle is a frequent nitrogen plant start up problem. Incorrect expansion valve settings, unstable liquid levels, or improper pressure ratios cause uneven cooling and slow cold box cooldown.

Impact:

• Temperature fluctuations

• Longer startup time

• Reduced separation efficiency

• Risk of cold box thermal stress

Fix:

Check expansion valve control, stabilize liquid inventory, and maintain steady HP/LP pressure ratios. Verify expander performance before increasing plant load.

7️⃣ CO₂ and Moisture Breakthrough Risks During Nitrogen Plant Start Up

Problem:

Moisture or CO₂ slip from molecular sieve beds is one of the most dangerous nitrogen plant start up problems. These contaminants freeze instantly inside the cold box and restrict flow.

Impact:

• Ice formation in exchangers

• Pressure drop increase

• Column instability

• Reduced nitrogen purity

Fix:

Regenerate dryers at correct temperature and cycle time. Confirm stable dew point and CO₂ readings before switching beds or starting cooldown.

8️⃣ Cold Box Temperature Imbalance - Critical Nitrogen Plant Start Up Problems

Problem:

Uneven temperature profiles during cooldown are a hidden nitrogen plant start up problem that can damage aluminum plate-fin heat exchangers and reduce plant reliability.

Impact:

• Thermal shock

• Flow maldistribution

• Purity fluctuations

Fix:

Cool down gradually. Monitor temperature differentials and flow balance across exchanger passes. Avoid rapid load changes during early startup.

9️⃣ Instrument Air or Control Power Issues

Unstable instrument air or power supply causes valve malfunction and false signals — a common yet overlooked nitrogen plant start up problem.

Impact:

• Control loop instability

• Unexpected trips

• Erratic purity readings

Fix:

Maintain clean, dry instrument air. Verify uninterrupted power supply, backup systems, and analyzer calibration before commissioning.

To ensure commissioning decisions are based on reliable data, the instrument validation checklist provides a structured method for verifying sensor accuracy, loop integrity, and signal consistency before relying on live readings.

🔟 Inadequate Operator Familiarity

Problem:

Lack of training during commissioning leads to incorrect valve sequences, missed interlocks, and frequent manual interventions — resulting in repeated nitrogen plant start up problems.

Impact:

• Slow stabilization

• Incorrect adjustments

• Higher shutdown risk

Fix:

Conduct structured pre-startup walkthroughs, P&ID reviews, and simulation exercises. Use standardized procedures and checklists for every startup.

Conclusion

Building Reliable Plants Starts with Preparation

Most nitrogen plant start up problems are preventable. With proper pretreatment control, refrigeration balance, instrumentation accuracy, and structured commissioning procedures, engineers can achieve smooth startup and stable long-term operation.

At Graphic Medium Industrial, we convert real commissioning experience into practical tools, checklists, and digital resources to help engineers diagnose faster and avoid costly downtime.

We provide:

• Free Diagnostic & Commissioning Checklists

• Micro-Books for focused troubleshooting

• Cryogenic Nitrogen Plant Troubleshooting Toolkit

• Remote & on-site consulting support

• Structured training resources for operators

Need expert support during commissioning or stabilization?

We provide selective industrial consulting for cryogenic nitrogen plants — focused on startup stability, purity recovery, and performance improvement.

Pingback: Essential Safety Tips for Cryogenic Nitrogen Plants - graphicmedium

Pingback: The Future of Industrial Training: Why Digital Learning is Transforming Engineering - graphicmedium