Safety Guidelines for Cryogenic Systems

Practical Safety Measures for Engineers, Operators & Technicians

Cryogenic systems operate at temperatures below –150°C and involve gases such as liquid nitrogen, oxygen, and argon.

These systems are widely used in metal processing, food freezing, electronics manufacturing, and medical gas applications — but they also present significant operational hazards.

This article outlines essential cryogenic safety guidelines to help engineers and operators understand key risks and follow structured good practices when working with liquid nitrogen, oxygen, or argon systems.

This guide supports safe operations by highlighting procedures that help prevent accidents, cold-burn injuries, and equipment-related failures.

📘 Free Resource: Download the Safety Guidelines for Cryogenic Systems (PDF) at the end of this page.

Understanding Cryogenic Hazards

Working with cryogenic fluids involves both physical and environmental risks. Understanding the main hazards is the first step toward applying effective cryogenic safety guidelines in industrial environments.

Common Hazards

Extreme Cold

Direct contact can cause severe cold burns or embrittle materials.

Asphyxiation Risk

Boil-off gases can displace oxygen in confined or poorly ventilated areas.

Pressure Build-up

Trapped liquid expands rapidly as it warms, increasing the risk of vessel rupture if pressure is not relieved properly.

Material Failure

Metals, seals, and gaskets can lose strength and flexibility at cryogenic temperatures.

Safety Tip

Always treat every cryogenic vessel as a potential pressure source — even when it appears empty.

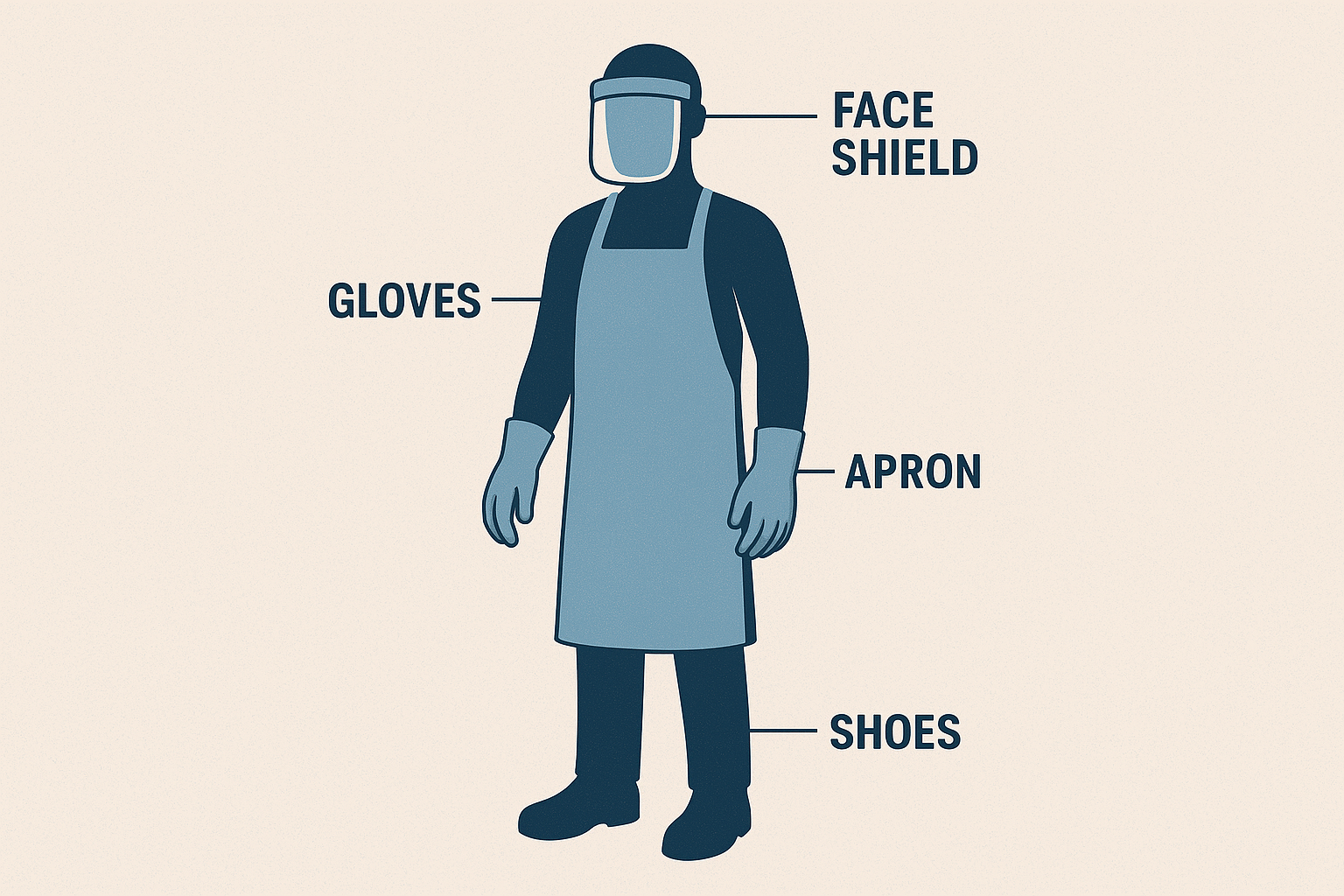

Personal Protective Equipment (PPE)

Proper PPE is the foundation of all cryogenic safety guidelines. It protects against extreme cold, liquid splashes, and vapor exposure during routine handling and operations.

Required PPE for Cryogenic Handling

Cryogenic gloves (loose-fitting and insulated)

Face shield + safety goggles (anti-fog recommended)

Non-absorbent apron or lab coat

Full-length pants and closed-toe safety shoes

Best Practices

Avoid wearing watches, jewelry, or anything that can trap liquid against the skin.

Replace damaged or stiff gloves immediately.

Inspect all PPE before use to ensure there is no cracking, hardening, or moisture.

Safety Reminder

Even brief contact with cryogenic liquid or vapor can cause severe cold burns — never underestimate the risk of near-field exposure.

Handling, Transfer & Storage Safety

Following standardized cryogenic safety guidelines helps ensure the safe handling of dewars, transfer hoses, and pressurized containers. Proper techniques reduce the risk of cold burns, overpressure, and oxygen displacement hazards.

Safe Handling Practices

Use only vented, rated containers for liquid transfer.

Open valves slowly to prevent sudden pressure surges.

Perform all operations in well-ventilated areas to avoid oxygen depletion.

Avoid leaning directly over open dewars, fill ports, or transfer lines.

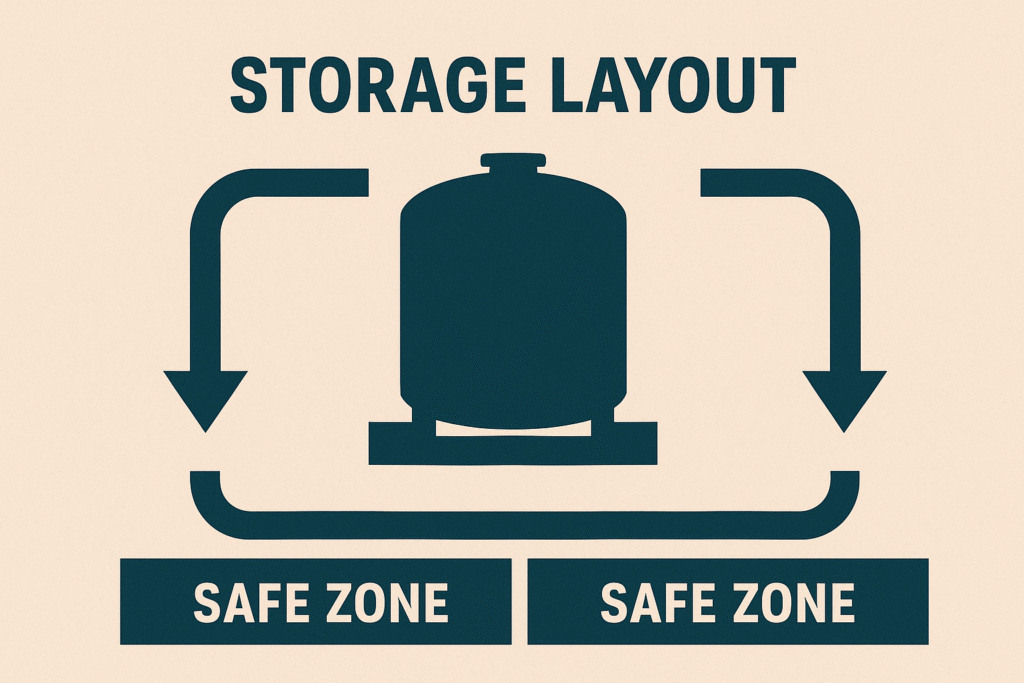

Storage Guidelines

Keep dewars upright on firm, level surfaces.

Maintain clearances from walls, heat sources, and electrical panels.

Inspect safety relief valves and vacuum insulation regularly.

Label all storage areas with appropriate hazard signage.

Safety Tip

Never trap cryogenic liquid between two closed valves — warming can cause it to expand more than 700 times in volume, creating an extreme overpressure hazard.

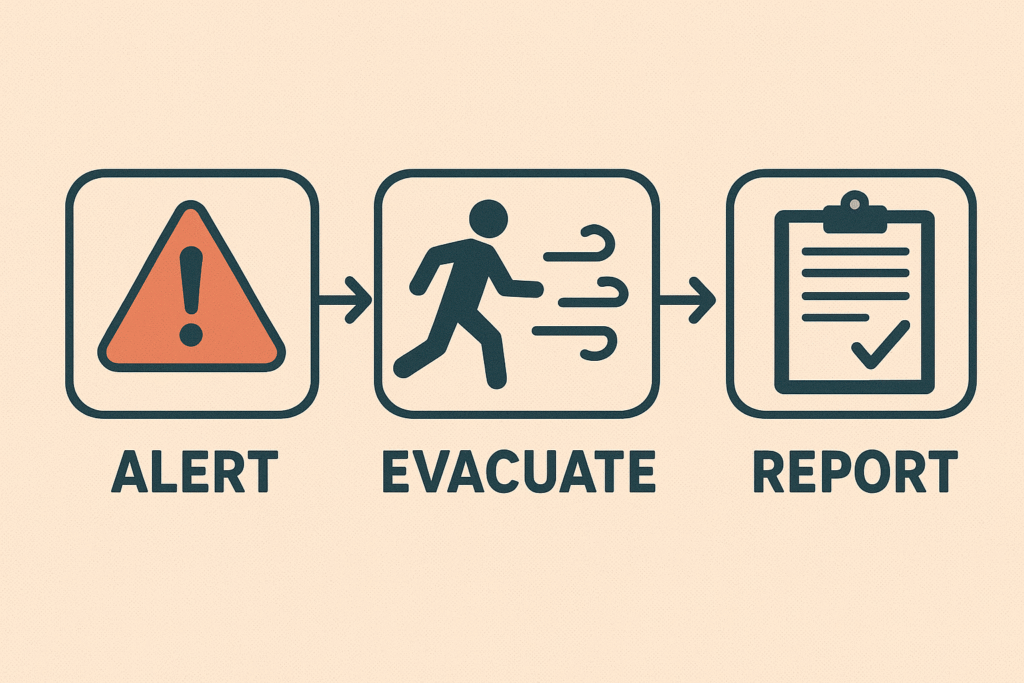

Emergency Procedures

Emergency response is a crucial part of cryogenic safety guidelines, helping prevent escalation during leaks, frostbite incidents, or oxygen-deficiency risks.

In Case of a Leak or Spill

Evacuate the area immediately.

Avoid touching frosted valves, pipes, or surfaces.

Ventilate the space thoroughly before re-entry.

Notify the designated safety officer or control room.

First Aid Measures

Frostbite:

Do not rub or massage the affected skin.

Warm gently using lukewarm (not hot) water.

Seek medical attention as soon as possible.

Fire or Oxygen-Enriched Area

Isolate the source only if it is safe to do so.

Evacuate the area and follow the facility’s emergency response plan.

Ensure all personnel are accounted for at designated muster points.

Additional Resource

Explore the Cryogenic Plant Commissioning Checklist (Free PDF) for pre-operation safety considerations and structured validation steps.

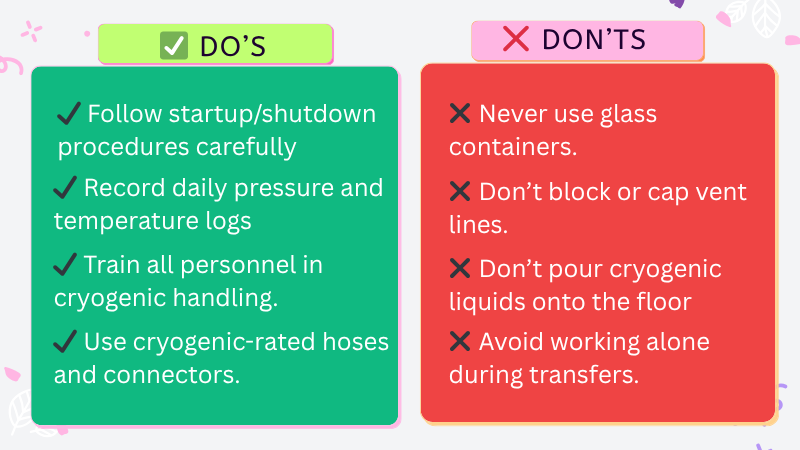

Key Do’s and Don’ts

The following checklist summarizes core cryogenic safety guidelines that plant operators should follow as part of daily operations.

Do’s

Don’ts ❌

✖ Never use glass or non-rated containers for cryogenic liquids.

✖ Do not block, cap, or restrict vent lines.

✖ Avoid pouring liquid nitrogen onto the floor to “evaporate.”

✖ Never perform cryogenic transfer operations alone — always work in teams.

“Read our Troubleshooting Guide for Nitrogen Plants to explore common issues and practical approaches to preventing process disruptions.

For teams focused on pre-start checks and first cool-down, the Commissioning Toolkit supports earlier phases, while the Troubleshooting Toolkit is better suited for diagnosing steady-state operating problems.

This cryogenic nitrogen plant safety documentation provides general guidance and documentation structure only.

Always follow:

Site-specific safety procedures

OEM manuals

Statutory and regulatory requirements

Always follow applicable statutory requirements and recognized safety standards, such as guidance issued by relevant regulatory authorities.

Safety — The Foundation of Every Cryogenic Operation

Safety in cryogenic systems is not just a checklist — it is a continuous culture of awareness, discipline, and responsible operation.

By following these best practices, you help reduce the risk of accidents, equipment issues, and unplanned downtime, supporting long-term system reliability and safer day-to-day operations.

At Graphic Medium Industrial, we believe cryogenic safety guidelines are not just procedural steps — they represent a mindset that supports long-term reliability, awareness, and safe operations across all cryogenic systems.

Our focus is on transforming complex industrial concepts into clear, accessible digital knowledge that empowers engineers and operators to work safer, smarter, and faster.