Cryogenic Nitrogen Plant

Commissioning Checklist” (PDF)

Commissioning is the critical stage where a nitrogen plant moves from construction to full-scale operation — the point at which every component truly comes to life. Each subsystem, from air compression to product delivery, must be checked for safety, performance, and compliance to ensure smooth and reliable functionality.

At Graphic Medium Industrial, we emphasize that success during this phase depends on structure, documentation, and precision. That’s why we’ve developed this cryogenic nitrogen plant commissioning checklist — a practical, industry-informed guide designed to help engineers and technicians follow each key step with clarity and confidence. It supports safe, efficient start-up while helping reduce avoidable errors and delays.

Why Commissioning Matters in Cryogenic Nitrogen Plants

Commissioning is the critical stage where a nitrogen plant transitions from construction to live operation. Each subsystem — from air compression to product delivery — must be verified for safety, performance, and compliance.

At Graphic Medium Industrial, we emphasize that successful cryogenic nitrogen plant commissioning depends on structure, documentation, and precision. Our cryogenic nitrogen plant commissioning checklist is designed as an industry-informed guide to help engineers and technicians follow every key step, supporting a smooth, safe, and efficient startup.

Pre-Commissioning Readiness

Before starting any operation, ensure that every mechanical, electrical, and control component is ready for live testing as outlined in the cryogenic nitrogen plant commissioning checklist.

Checklist Items:

-

Verify mechanical completion certificates for all equipment.

-

Inspect alignment and foundation bolts for compressors and pumps.

-

Confirm all piping systems are pressure-tested and leak-free.

-

Check instrument calibration reports (pressure, temperature, flow, level).

-

Ensure electrical panels are energized and interlocks are tested.

-

Review safety and lockout/tagout procedures.

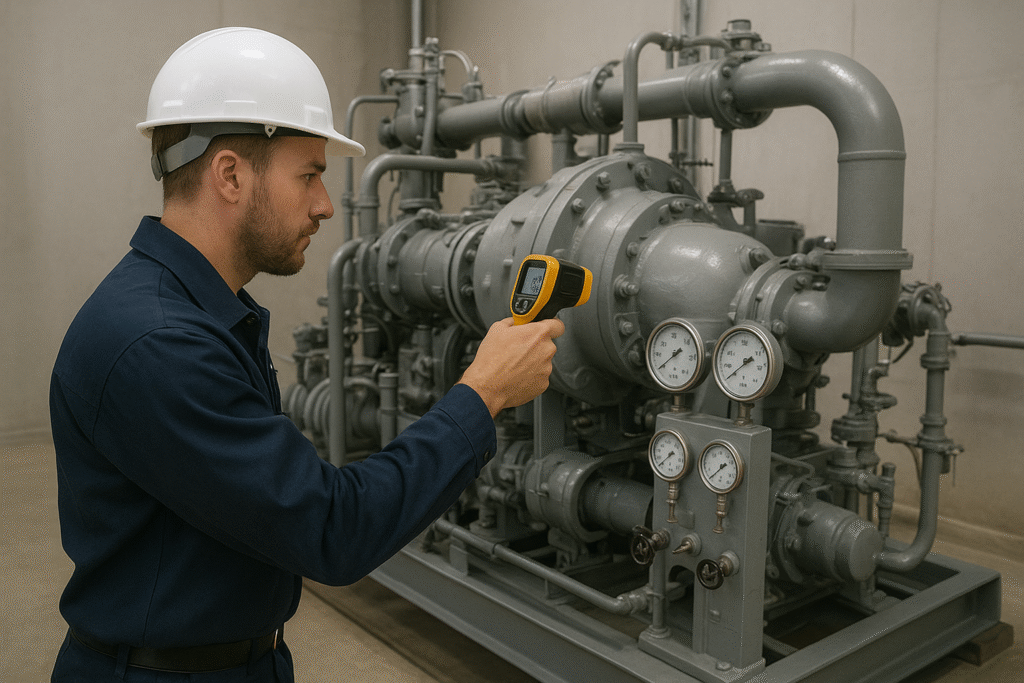

Air Compression & Cooling System Checks

Air preparation sets the foundation for nitrogen purity and plant stability. As part of the cryogenic nitrogen plant commissioning checklist, this stage ensures all air-handling and refrigeration systems are operating within design parameters.

Checklist Items:

-

Inspect compressor oil levels, filters, and intercoolers.

-

Verify suction and discharge pressures per OEM specs.

-

Confirm correct motor rotation and alignment.

-

Test refrigeration compressor suction/discharge pressures.

-

Monitor chiller outlet temperature and expansion valve operation.

-

Verify refrigerant charge and ensure no frost formation in lines.

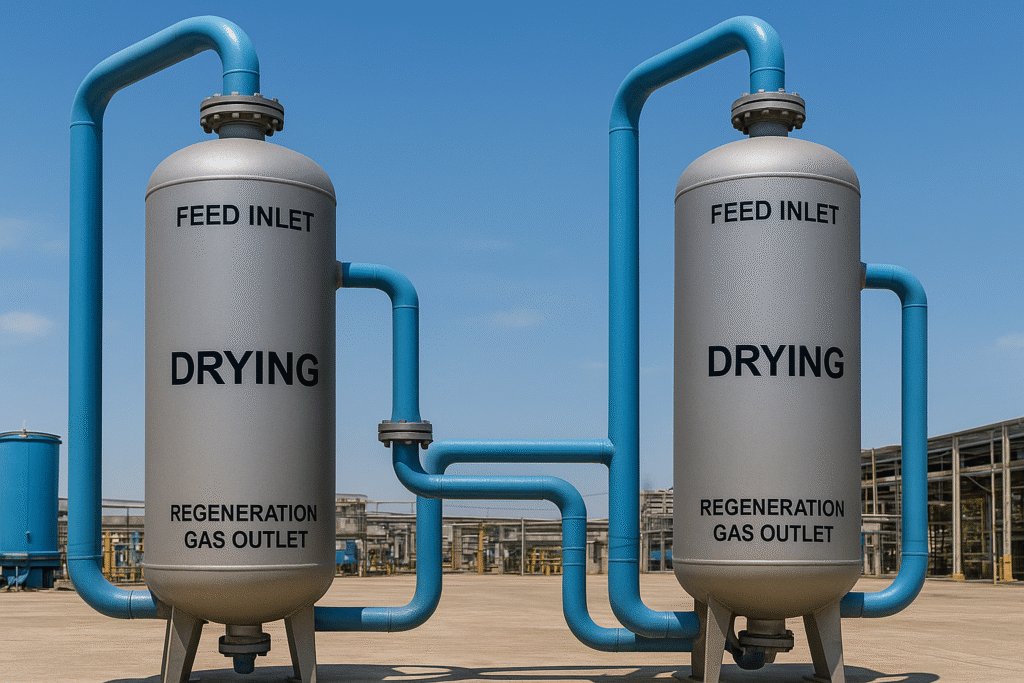

Purification Unit Checks (Moisture & CO₂ Removal)

Air purification ensures contaminants are removed before entering the cryogenic cold box. This stage of the cryogenic nitrogen plant commissioning checklist focuses on verifying that all purification systems operate efficiently to protect downstream cryogenic equipment.

Checklist Items:

-

Check bed heating and cooling cycle timing.

-

Verify heater element resistance and temperature sensors.

-

Confirm CO₂ analyzer readings are within limit.

-

Inspect molecular sieve or activated alumina condition.

-

Check valve sequencing in PLC logic.

-

Ensure regeneration flow is stable and complete.

Cold Box and Separation System

This is the heart of cryogenic nitrogen production — where air separation happens. As a crucial part of the cryogenic nitrogen plant commissioning checklist, this stage ensures that all cold box and air separation components function precisely under cryogenic conditions.

Checklist Items:

-

Confirm vacuum insulation integrity (no loss in pressure).

-

Check cryogenic valve actuators for smooth function.

-

Monitor temperature gradients across heat exchangers.

-

Verify column pressure and reflux ratios.

-

Ensure analyzers are calibrated and stable.

-

Record liquid levels and pressure in main exchanger and columns.

Product Storage and Delivery Checks

Final stage — where liquid and gaseous nitrogen are stored and dispatched. This step of the cryogenic nitrogen plant commissioning checklist focuses on verifying storage integrity, product purity, and safe transfer operations before full-scale production begins.

Checklist Items:

-

Check product tank pressure and safety relief valve settings.

-

Verify liquid nitrogen transfer line insulation.

-

Test loading line and vaporizer operation.

-

Confirm product purity (O₂ < 10 ppm or per spec).

-

Ensure vent valves are operational and ice-free.

-

Validate emergency shutdown and alarm response.

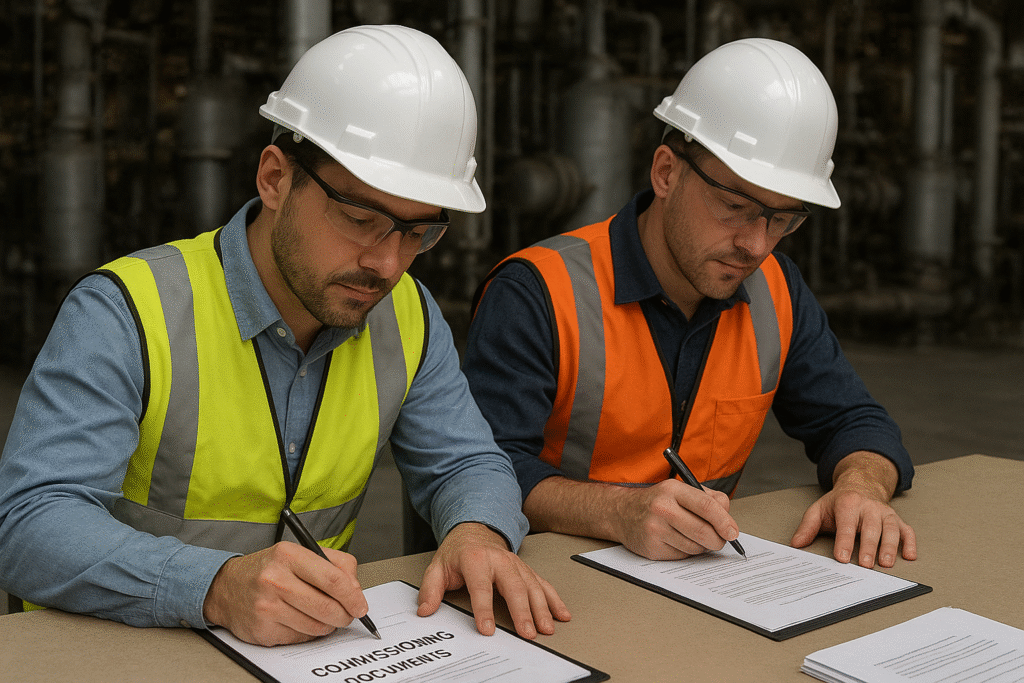

Performance and Final Handover

-

-

Record plant load and purity for a 72-hour performance run.

-

Verify system stability at minimum and maximum load.

-

Document process parameters, alarms, and trip logs.

-

Calibrate analyzers post-run.

-

Obtain client/operator performance sign-off. Once startup is complete, the focus shifts to system optimization and documentation. As part of the cryogenic nitrogen plant commissioning checklist, this phase ensures the plant operates reliably under all load conditions and that comprehensive records are maintained for performance validation.

-

For teams focused on pre-start checks and first cool-down, the Commissioning Toolkit supports earlier phases, while the Troubleshooting Toolkit is better suited for diagnosing steady-state operating problems.

Aligning with applicable OSHA’s workplace safety requirements and widely recognized ASME engineering standards helps ensure that each test in the cryogenic nitrogen plant commissioning checklist follows established industry expectations for safety and compliance. commissioning checklist meets international compliance benchmarks.

Final Thoughts — Structured Commissioning Saves Time

Commissioning a cryogenic nitrogen plant is where design meets performance. Using a structured cryogenic nitrogen plant commissioning checklist not only ensures safety and reliability but also builds operational confidence.

By standardizing every check within the cryogenic nitrogen plant commissioning checklist, you help minimize human error, accelerate startup, and enhance product quality.

For guidance on resolving post-startup issues, refer to Common Troubleshooting Issues in Nitrogen Plants.

To support safe and compliant operation, see Safety Guidelines for Cryogenic Systems — an educational resource designed to reinforce best practices.