Why Nitrogen Plants Fail Performance Guarantee Tests (and How to Recover)

A nitrogen plant performance guarantee failure is one of the most stressful events during commissioning. After months of installation and startup, the plant is expected to meet contractual purity, flow, and energy targets — yet many cryogenic nitrogen plants fail their first performance guarantee (PG) test.

When this happens, projects face:

Payment delays

Contractual penalties

Client disputes

Forced troubleshooting under time pressure

The good news?

Most nitrogen plant performance guarantee failures are predictable and recoverable when diagnosed systematically.

In this guide, you’ll learn:

What PG tests really evaluate

Why nitrogen plants fail performance guarantees

How to diagnose failures correctly

Step-by-step recovery methods

👉 Download the Free Commissioning & Performance Test Readiness Checklist (PDF) to verify readiness before scheduling your next test.

What Is a Performance Guarantee Test in Nitrogen Plants?

A performance guarantee test verifies whether the plant achieves its contractual design performance under steady-state conditions.

Typical guarantees include:

Nitrogen purity (% or ppm O₂)

Product flow rate

Specific power consumption (kWh/Nm³)

Continuous stable operation

Passing the test is mandatory for:

Final project acceptance

Warranty handover

Release of milestone payments

Failing the test results in a nitrogen plant performance guarantee failure, triggering corrective action and often re-testing.

For background on structured commissioning practices that prevent these issues, see our detailed Cryogenic Nitrogen Plant Commissioning Guide.

Why Nitrogen Plant Performance Guarantee Failure Happens (Even When the Plant Is “Running”)

Many plants appear operational but still fail PG tests because hidden inefficiencies only become visible during strict performance measurement.

Below are the most common root causes.

1️⃣ Incomplete Commissioning & Stabilization

If commissioning is rushed:

Control loops remain poorly tuned

Columns not fully stabilized

Temperature profiles still drifting

PG tests require steady-state operation, not “just running.”

Plants that skip structured commissioning frequently experience nitrogen plant performance guarantee failure.

2️⃣ Pretreatment System Underperformance

Pretreatment issues are the #1 hidden cause.

Moisture or CO₂ breakthrough leads to:

Partial exchanger freezing

Reduced heat transfer

Higher pressure drop

Lower capacity

Even minor contamination can reduce cold box efficiency during testing.

If you suspect pretreatment weakness, review our guide on How to Diagnose Molecular Sieve Failure in Nitrogen Plant Pretreatment Systems.

Compressor & Expander

Compressor & Expander

Inefficiencies

Refrigeration imbalance reduces separation efficiency.

Common problems:

Incorrect loading

Vibration limits

Seal gas instability

Reduced expander output

Less refrigeration → lower purity and flow → PG failure.

4️⃣ Heat Exchanger Fouling or Maldistribution

Often caused by earlier freezing or contamination:

Temperature pinch increases

Pressure drop rises

Capacity drops

This frequently links back to cold box freezing risks, explained here:

5️⃣ Instrumentation & Analyzer Errors

Surprisingly common.

During PG tests:

Flow meter calibration errors

Analyzer lag

Power meter inaccuracies

can falsely indicate a nitrogen plant performance guarantee failure even when the plant is fine.

6️⃣ Operation Outside Design Envelope

Examples:

Wrong feed conditions

Ambient correction not applied

Improper operating modes

Guarantees only apply under defined conditions.

Warning Signs Before Performance Test Failure

If you see these, delay testing:

Difficulty stabilizing purity

Rising energy consumption

Increasing cold box pressure drop

Frequent alarms or trips

Testing during instability almost guarantees performance guarantee failure.

How to Diagnose Nitrogen Plant Performance Guarantee Failure

Follow a structured approach.

Step 1 – Verify Measurements

Confirm:

Flow meters calibrated

O₂ analyzers validated

Power meters accurate

Bad data = false failure.

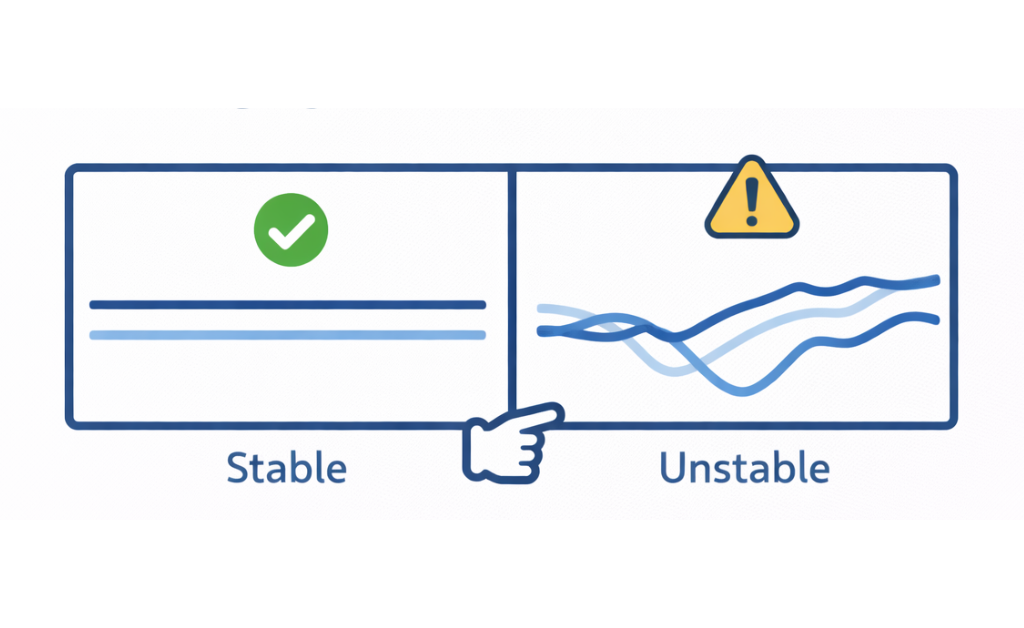

Step 2 – Confirm Steady State

Trend for 24–48 hours:

Temperature

Pressure

Purity

Compressor load

No drift allowed during test window.

Step 3 – Check Refrigeration Balance

Verify:

Expander efficiency

Compressor discharge temp

Heat exchanger approach

Refrigeration loss directly causes nitrogen plant performance guarantee failure.

Step 4 – Reassess Pretreatment

Check:

Dew point stability

CO₂ breakthrough

Regeneration effectiveness

Pretreatment issues often appear as “cold box inefficiency.”

Step 5 – Review Control Strategy

Confirm:

Loop tuning

Valve response

Minimal manual intervention

Frequent operator corrections = unstable process.

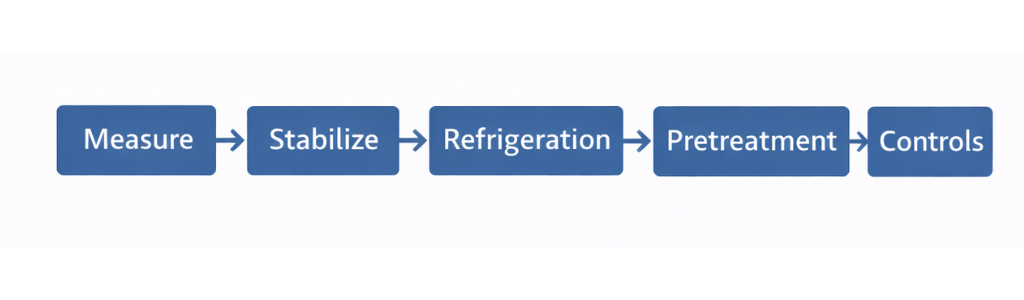

How to Recover After PG Test Failure

Stabilize Before Retesting

Never rush.

Fix root causes

Validate stability

Run internal trials

Remove

Bottlenecks

Examples:

Improve adsorber regeneration

Correct compressor loading

Fix exchanger maldistribution

Re-Tune

Controls

Proper tuning improves:

Column stability

Energy efficiency

Product consistency

Validate Test Conditions

Ensure:

Correct ambient correction

Proper feed specs

Contract test procedure followed

Tools That Reduce Nitrogen Plant Performance Guarantee Failure

Structured tools prevent guesswork.

The Commissioning & Stability Toolkit includes:

PG readiness checklists

Refrigeration balance logs

Pretreatment validation sheets

Test execution templates

When to Seek Expert Engineering Support

Call specialists when:

-

Repeated PG failures occur

-

Cold box damage suspected

-

Mechanical efficiency unclear

-

Contract deadlines critical

External Technical Reference

For deeper theoretical background on cryogenic separation and performance principles, engineers may consult:

Air Products – Cryogenic Nitrogen Generation Systems Technical Resources

https://www.airproducts.com

❓ FAQ

What is the most common cause of nitrogen plant performance guarantee failure?

Pretreatment breakthrough or refrigeration imbalance.

Can PG tests be repeated?

Yes, but repeated failures increase contractual risk.

Do purity failures mean column design problems?

Usually not — most are operational or pretreatment related.

Is energy consumption always part of PG tests?

Often yes for medium and large plants.

Final Takeaway

A nitrogen plant performance guarantee failure is rarely caused by a single fault. It results from small inefficiencies accumulating across pretreatment, refrigeration, controls, and operation.

Plants that use structured diagnosis and readiness checks consistently pass PG tests faster — with fewer disputes and less downtime.

Passing PG tests isn’t luck — it’s disciplined engineering.