Cold Box Freezing in Nitrogen Plants:

Causes, Early Warning Signs & Recovery Steps

Cold box freezing in nitrogen plants is one of the most serious and costly operational problems encountered during commissioning and operation. When freezing develops inside the cold box, it leads to flow restrictions, unstable separation, nitrogen purity loss, and in severe cases, complete plant shutdown.

What makes cold box freezing in nitrogen plants particularly dangerous is that it usually begins internally, long before visible alarms, trips, or mechanical failures appear. By the time operators react, significant internal restriction may already be present.

In this guide, we explain why cold box freezing occurs, how to identify early warning signs, what actions to take during operation, and how engineers can prevent repeat freezing events.

A structured diagnostic approach is essential. Engineers often rely on tools such as the CO₂ & Moisture Impact Diagnostic Sheet, which helps identify adsorption breakthrough, moisture ingress, and freezing risk before irreversible damage occurs.

A field-ready checklist to identify adsorption breakthrough, moisture ingress, and freezing risks before serious damage occurs.

What Does “Cold Box Freezing” Actually Mean?

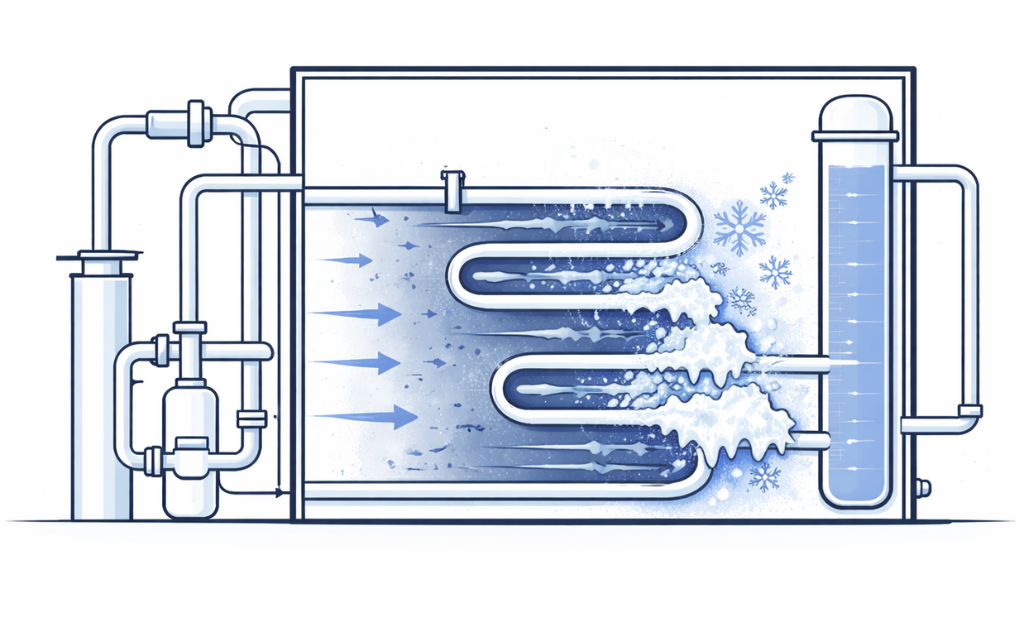

Cold box freezing in nitrogen plants refers to the formation of ice (from moisture) or solid CO₂ inside cryogenic heat exchangers, piping, or column internals housed within the cold box. Because operating temperatures are extremely low, even trace quantities of moisture or CO₂ can solidify and accumulate over time.

Once freezing begins, it can block internal flow paths, increase pressure drop across exchangers, disturb column temperature profiles, and reduce overall heat exchanger efficiency. Since these effects develop inside enclosed equipment, freezing often progresses unnoticed until operational instability becomes severe.

Cryogenic engineering literature and industrial gas references consistently show that CO₂ and moisture solidification at low temperatures is one of the primary risks in air separation and nitrogen production systems.

Why Cold Box Freezing Is So Dangerous

Unlike mechanical failures, cold box freezing is a process contamination problem. It spreads internally, is difficult to detect visually, and often accelerates once it begins.

Major risks include sudden pressure buildup within heat exchangers, distorted separation inside distillation columns, expander and compressor instability, and long downtime due to forced warm-up and internal drying. In many nitrogen plants, freezing incidents recur because the true root cause—often upstream—is not fully identified.

Primary Causes of Cold Box Freezing in Nitrogen Plants

1. Moisture Breakthrough from Pretreatment

Moisture breakthrough from pretreatment is the most common cause of cold box freezing in nitrogen plants. This typically results from molecular sieve saturation, incomplete regeneration, valve leakage during adsorber switching, or insufficient drying during startup.

Even moisture present at parts-per-million levels can freeze inside cryogenic exchangers and gradually accumulate. Many freezing incidents can be traced back to degraded pretreatment system performance during unstable startup conditions.

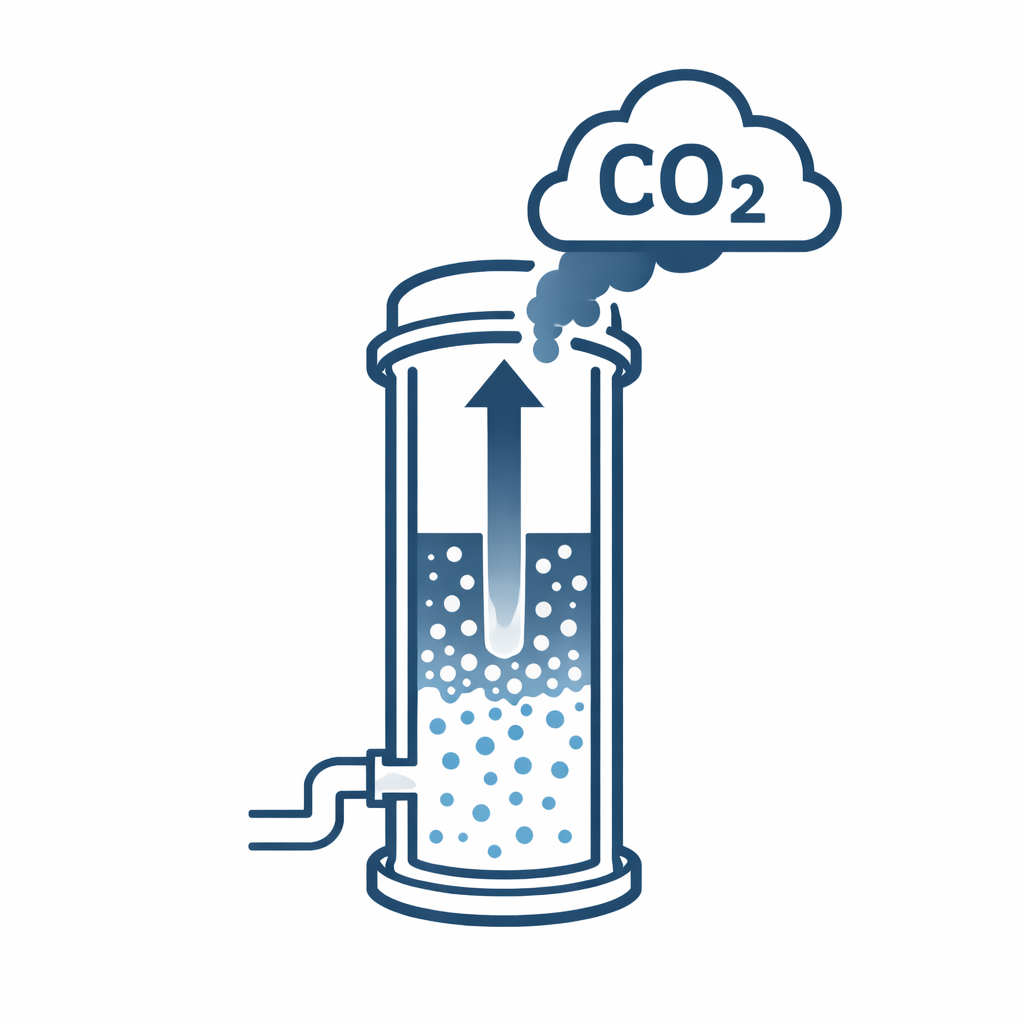

2. CO₂ Breakthrough After Adsorbers

CO₂ solidifies at cryogenic temperatures and forms hard blockages inside heat exchangers and cold piping. This may occur due to incorrect regeneration temperature, channeling within adsorber beds, bed aging, contamination, or sudden load changes.

CO₂ freezing often manifests as a gradual but persistent increase in pressure drop rather than an immediate alarm, making it especially dangerous if trends are not monitored closely.

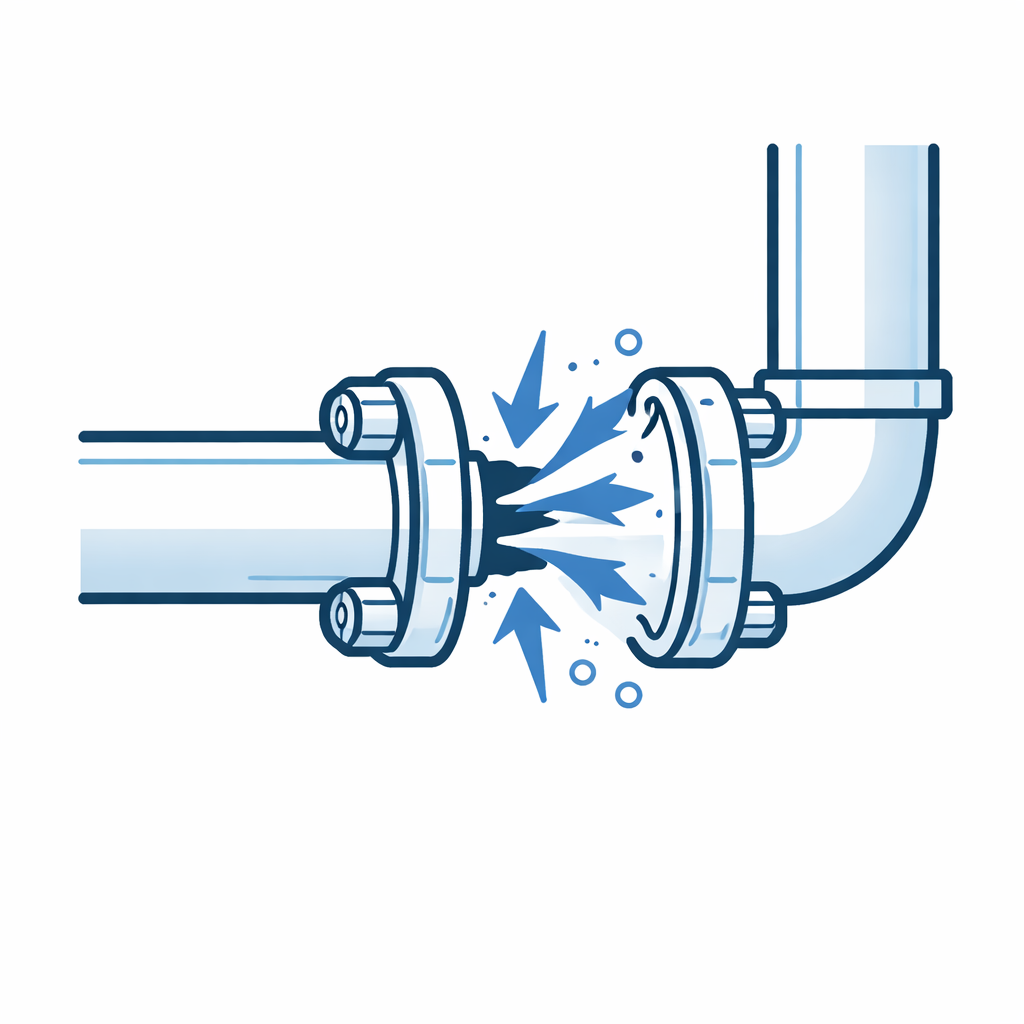

3. Air Ingress or Leakage Points

Air ingress introduces both moisture and CO₂ directly into cold sections of the plant. Common ingress locations include flange joints, instrument connections, impulse lines, and maintenance openings that are not properly sealed.

Because many cold box sections operate under partial vacuum, even very small leaks can draw contaminants inward and initiate freezing.

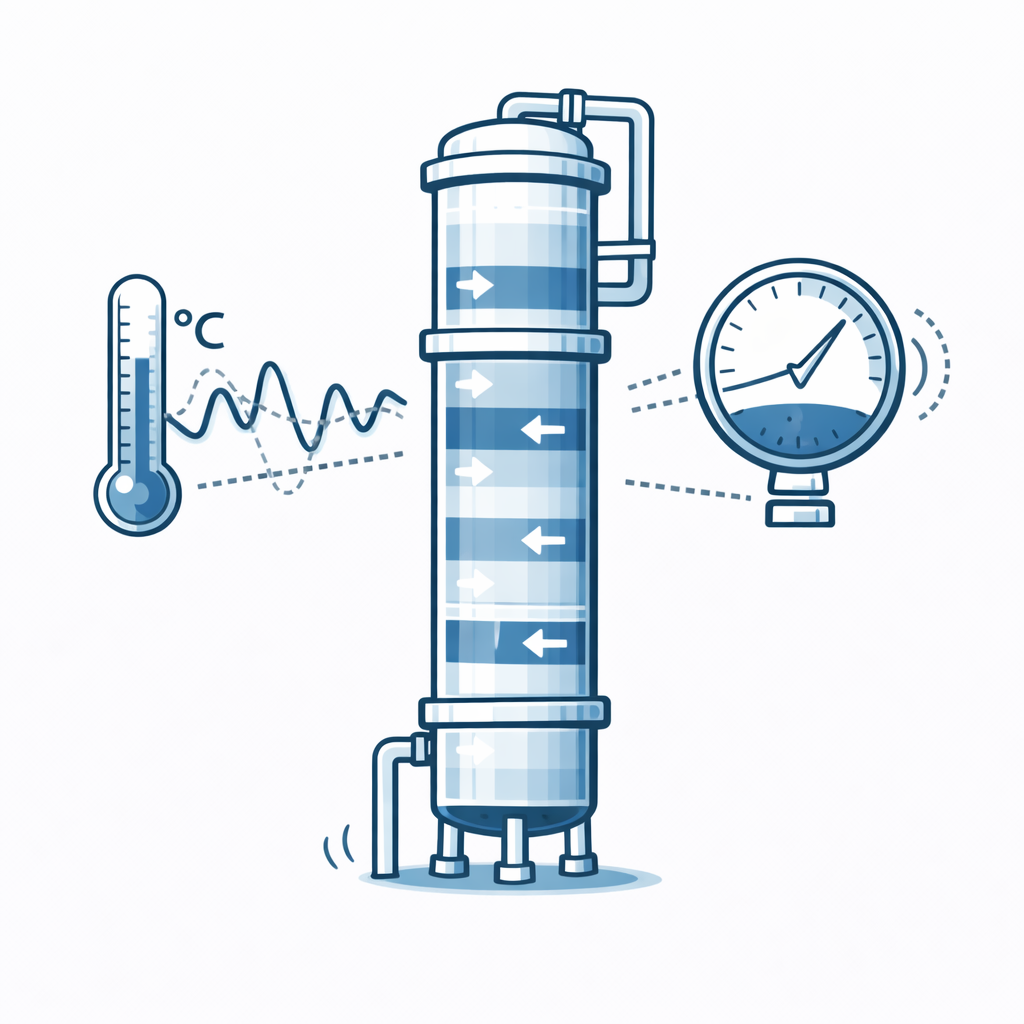

4. Inadequate Cooldown Procedures

Improper or rushed cooldown procedures significantly increase freezing risk. Rapid cooldown can condense residual moisture, create uneven freezing zones, and mask early blockage formation.

Cooldown is not simply a temperature reduction step; it is a critical freeze-risk management process that must be controlled and verified as part of structured nitrogen plant commissioning practices.

👉 Use the CO₂ & Moisture Diagnostic Sheet to systematically log these indicators before freezing becomes critical.

Early Warning Signs Engineers Should Watch

Cold box freezing rarely occurs suddenly. It develops gradually and provides clear early indicators for engineers who monitor trends carefully.

Rising Pressure

Drop

A rising pressure drop across the main heat exchanger, specific exchanger passes, or column inlet sections is often one of the first signs

Temperature Profile Distortion

Temperature profile distortion, including abnormal cold spots, sudden gradients, or slower-than-expected cooldown response, is another strong indicator.

Column Instability

Column instability may appear as fluctuating nitrogen purity, unstable reflux control, or pressure oscillations.

Increased Energy Consumption

Energy consumption often increases as compressors and expanders work harder to overcome internal restrictions.

What To Do If Freezing Is Suspected

Step 1: Do NOT Increase Load

If freezing is suspected, the first rule is to avoid increasing plant load. Higher flow rates usually worsen ice formation and accelerate blockage.

Step 2: Stabilize and Reduce Throughput

Lower process flow gradually

Stabilize column operation

Avoid aggressive control changes

Step 3: Warm-Up Affected Sections If Required

Depending on severity:

Controlled warm-up may be necessary

Purge with dry nitrogen

Prevent water condensation during warm-up

⚠️ Uncontrolled warm-up can cause thermal stress and further damage.

Step 4: Investigate Pretreatment Immediately

Before restarting:

Verify adsorber performance

Check dew point and CO₂ levels

Confirm regeneration sequences

Restarting without fixing pretreatment almost guarantees recurrence.

How to Prevent Repeat Freezing Events

1. Improve Pretreatment Monitoring

Continuous dew point monitoring

CO₂ analyzer validation

Trend logging during load changes

2. Follow Structured Startup & Cooldown Procedure

Avoid:

Rushing cooldown steps

Skipping verification holds

Ignoring temperature gradients

Cooldown curves should be part of documented procedures, not operator memory.

3. Use Predictive Indicators, Not Only Alarms

Alarms act after damage begins. Best practice uses:

Pressure trend patterns

Temperature slope deviations

Adsorber cycle performance logs

This allows early intervention before ice formation blocks flow.

Engineers who rely on predictive indicators rather than alarms alone typically develop stronger diagnostic skills through structured digital learning for industrial engineers.

Tools That Help Prevent Freezing & Instability

To manage freezing risks systematically, many plants use structured field tools such as:

Moisture & CO₂ breakthrough diagnostic sheets

Cold box temperature mapping templates

Pretreatment performance checklists

Startup stabilization workflows

👉 These are included in the

Designed for engineers and operators to identify root causes, not just symptoms.

When Is Engineering Support Required?

You should consider expert support when:

Freezing recurs after corrective actions

Pressure drop continues increasing

Purity remains unstable after restart

Cold box internal damage is suspected

At this stage, structured diagnostic testing and process evaluation are required — not trial-and-error adjustments.

👉 Graphic Medium Industrial Consulting provides scope-defined troubleshooting and stabilization support based on real plant workflows.

FAQ

What is the most common cause of cold box freezing?

Moisture breakthrough from pretreatment due to poor regeneration or adsorber switching faults.

Can freezing occur even if analyzers show normal values?

Yes. Analyzer lag and sensor drift can hide early breakthrough while freezing develops internally.

Does freezing damage cold box internals permanently?

Repeated freeze-thaw cycles can deform packing and cause long-term performance loss.

Should operation continue if freezing is suspected?

No. Continuing operation usually worsens blockage and increases downtime risk.

Final Takeaway

Cold box freezing in nitrogen plants is not a random event. It is a predictable and preventable process failure. When pretreatment performance, cooldown profiles, and pressure trends are monitored correctly, freezing risks can be detected early and controlled safely.

👉 Recommended Next Actions

📥 Download Free CO₂ & Moisture Diagnostic Sheet

📘 Use the Troubleshooting Toolkit for Structured Diagnosis

🔧 Contact Industrial Consulting for Persistent Freezing Issues

Preventing freezing means protecting uptime, safety, and long-term plant performance.