Cryogenic ASU Training for Engineers -

From Fundamentals to Startup & Stability

This Cryogenic ASU Training for Engineers is designed to build real plant understanding of air separation processes, commissioning workflows, and stable cryogenic operations.

Our ASU training program focuses on how systems behave during pre-commissioning, startup, and normal operation — not just on equipment definitions.

New to cryogenic systems? Start with our Cryogenic Nitrogen Plant Knowledge Hub for process basics and equipment understanding.

Looking for site-specific or corporate training programs? Contact our engineering team to discuss customized training options.

Who Should Attend This Cryogenic ASU Training for Engineers

Designed for Engineers and Technical Learners

Commissioning Engineers

This Cryogenic ASU Training for Engineers helps commissioning teams understand cooldown risks, column loading, and stabilization procedures.

Commissioning engineers may also benefit from our Commissioning & Stability Toolkit for structured startup and handover activities.

Operations & Maintenance Teams

Operations teams benefit from this ASU operations training by learning how to detect early warning signs of process disturbances.

Operations teams can extend this learning with our Troubleshooting Toolkit for Cryogenic Nitrogen Plants covering alarms and instability patterns.

EPC & Project Engineers

EPC engineers gain value from this air separation unit training program by understanding how design, installation, and controls affect startup readiness.

EPC professionals can explore our industrial engineering consulting services for documentation, reviews, and commissioning support.

Engineering Students

Students preparing for careers in industrial gas plants can use this Cryogenic ASU Training for Engineers to bridge the gap between theory and real plant practice.

Students can strengthen fundamentals using our Cryogenic Micro-Books & Short Engineering Guides for structured self-study.

Why This Training Is Different

Built for Real Plants — Not Just Exams

Our approach focuses on:

🔧 Real commissioning sequences

📊 Control and instrumentation behavior

❄ Cryogenic risks and contamination mechanisms

🧠 Operator decision-making logic

You learn the cause-and-effect relationships that matter in actual plants.

Training Modules in Our Cryogenic ASU Training Course

The Cryogenic ASU Training for Engineers is structured into progressive modules covering fundamentals, equipment, commissioning readiness, and startup stability.

Module 1 —

Cryogenic Fundamentals

This Module of cryogenic air separation unit training explains gas behavior at low temperatures, heat exchange principles, and contamination risks.

-

Gas behavior at low temperatures

-

Heat exchange principles

-

Phase change and freezing risks

-

Why contamination is dangerous in cold systems.

-

Cryogenic separation principles follow established chemical engineering thermodynamics and heat-transfer theory.

Module 2 —

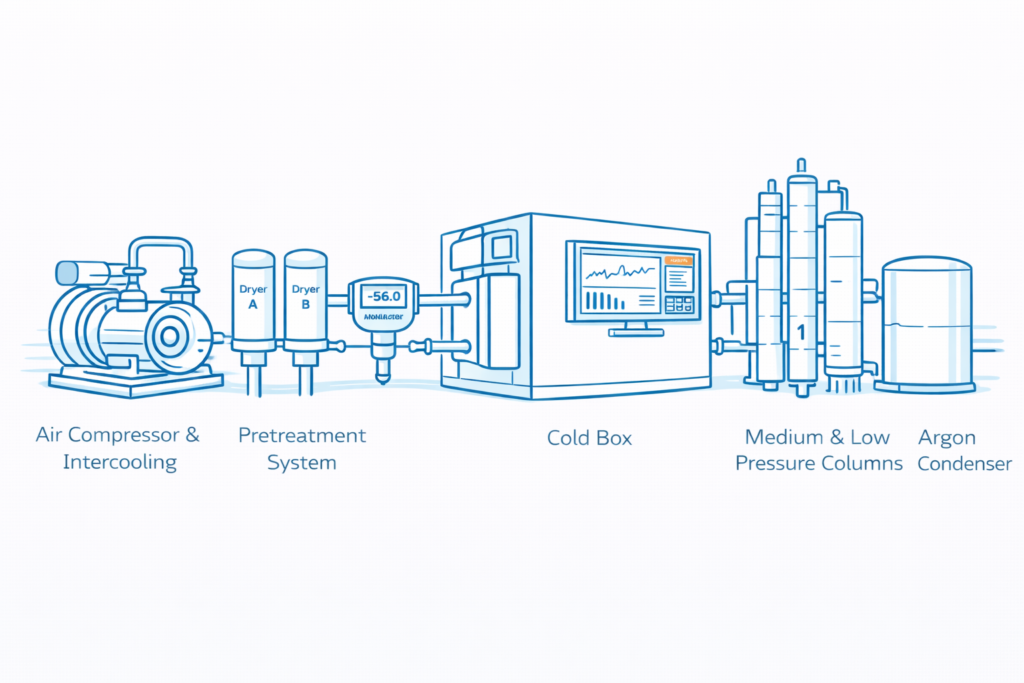

ASU Process & Major Equipment

This module forms the core of the ASU process training, covering compressors, pretreatment systems, cold box internals, and distillation columns.

Air compression and intercooling

Pretreatment system operation

Cold box heat exchanger concepts

Medium and low pressure columns

Product handling and utilities

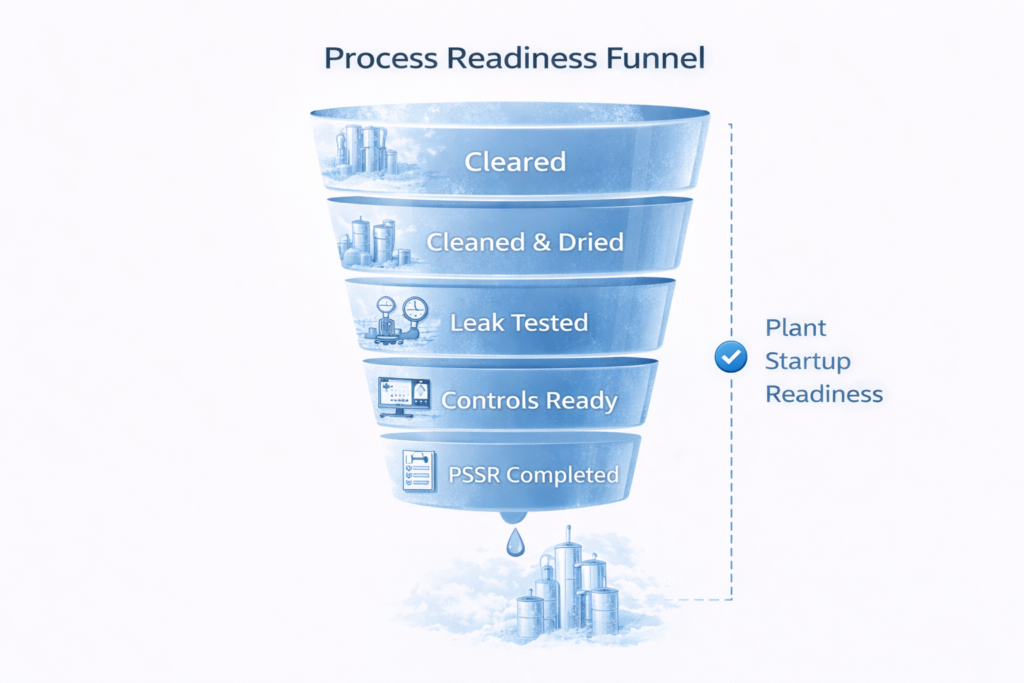

Module 3 — Pre-Commissioning for Cryogenic ASU

In this phase of the ASU commissioning training, engineers learn how mechanical completion, cleaning, drying, and control checks prevent cold box failures.

Mechanical completion verification

Cleaning and flushing of systems

Dry-out and moisture control

Leak testing methods

Control loop and safety system testing

Pre-Startup Safety Review (PSSR)

Module 4 — Startup, Cooldown & Stability Concepts

This part of the Cryogenic ASU Training for Engineers explains controlled cooldown, liquid formation, column stabilization, and early fault detection.

Safe cooldown philosophy

Liquid formation stages

Column stabilization

Product purity development

Common startup disturbances

Early warning signs of instability

Module 5 — Process Control & Instrumentation in Cryogenic ASU

This module of the Cryogenic ASU Training for Engineers focuses on how control systems and instrumentation influence plant stability, purity, and safe operation. Engineers learn how process signals, control logic, and valve behavior interact during startup and normal operation.

Key control loops in air compression and cold box systems

Column pressure and temperature control philosophy

Flow, pressure, and temperature measurement challenges in cryogenic service

Gas analyzers and moisture monitoring fundamentals

Control valve behavior and actuator limitations at low temperatures

Identifying control-related causes of instability

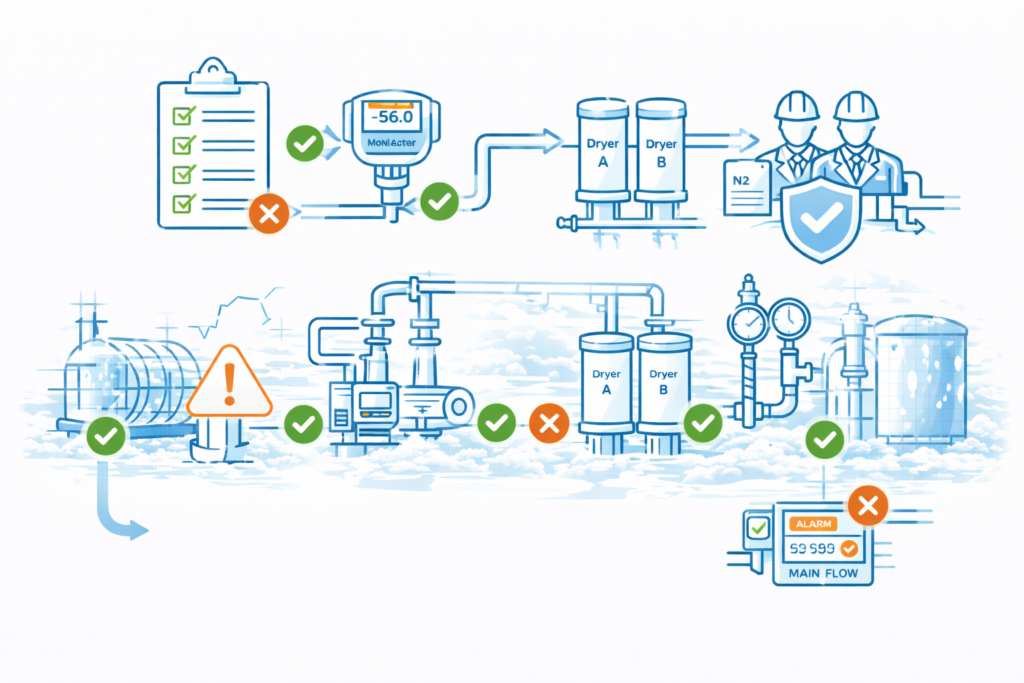

Module 6 — Troubleshooting & Abnormal Operation Handling

This module trains engineers to apply structured troubleshooting methods during unstable or abnormal plant conditions. Participants learn how to interpret trends, isolate root causes, and take corrective actions without worsening process disturbances.

Reading DCS trends and recognizing early warning signs

Common ASU disturbances and their process causes

Differentiating symptoms from root causes

Step-by-step fault isolation techniques

Stabilization strategies versus safe shutdown decisions

Case-based troubleshooting logic used in real plants

Module 7 — Safety, Interlocks & Operational Best Practices

This module covers safety systems, interlocks, and operational discipline required for cryogenic air separation units. Engineers learn how safety layers integrate with process controls to prevent incidents during startup, operation, and shutdown.

Cryogenic hazards and oxygen-enriched environment risks

Role of gas detection, alarms, and ESD systems

Interlocks, permissives, and startup safety logic

Pre-Startup Safety Review (PSSR) expectations

Incident prevention through operating discipline

Safe response to emergency and upset conditions

Module 8 — Career & Skill Development for Engineers

This module of the Cryogenic ASU Training for Engineers focuses on helping participants understand career pathways in industrial gas and cryogenic plant industries. Engineers learn what technical skills, site experience, and professional competencies are expected for commissioning, operations, and project roles.

Career roles in industrial gas plants and EPC projects

Skills required for commissioning, operations, and maintenance engineers

How to build plant-relevant technical competence beyond academics

Understanding site workflows and multidisciplinary coordination

Preparing for technical interviews and plant assignments

Continuous learning paths using toolkits, micro-books, and field exposure

How the Cryogenic ASU Training for Engineers Is Conducted

All sessions in this Cryogenic ASU Training for Engineers are conducted as live, instructor-led online classes with interactive explanations.

This online ASU training program allows working professionals and students to learn without site travel.

Live Online

Instructor-led sessions conducted in real time with direct interaction and Q&A.

Small Batch

Limited participants per session to ensure personalized attention and better discussions.

Interactive

Case-based learning with visuals, questions, and practical process scenarios instead of passive lectures.

What You Will Learn in This Cryogenic ASU Training

After completing this Cryogenic ASU Training for Engineers, participants will be able to understand startup risks, read instability trends, and respond safely to abnormal conditions.

Understand full ASU process flow and interactions

Recognize contamination and freezing risks early

Follow structured pre-commissioning logic

Interpret trends and operating disturbances

Communicate better with commissioning and operations teams

Avoid common startup mistakes

This air separation unit training course builds strong fundamentals for commissioning, operations, and troubleshooting roles in cryogenic plants.

Need expert guidance during commissioning or startup? Talk to an industrial engineering consultant for real-plant support.

Need Expert Help With Your Actual Cryogenic ASU Plant or Project?

Training builds your technical understanding.

Consulting helps you solve real plant challenges with expert guidance.

Along with this Cryogenic ASU Training for Engineers, you can also access one-to-one consulting support for commissioning, startup, and operational problem-solving.

Our Cryogenic ASU Consulting Sessions Support You With:

✔ Startup and cooldown sequence planning

✔ Troubleshooting abnormal plant behavior

✔ Process stability and purity issues

✔ Control and instrumentation review

✔ Commissioning workflow and readiness checks

✔ Documentation and operational decision support

How Cryogenic ASU Training Helps Your Engineering Career

Faster readiness for commissioning roles

Better confidence in startup & troubleshooting

Strong foundation for cryogenic plant interviews

Useful for EPC, OEM, and gas companies

Training Designed by Industrial Engineers, Not Generic Trainers

Based on real nitrogen plant commissioning experience

Used to build troubleshooting toolkits & documentation systems

Aligned with actual site workflows

Why Graphic Medium Industrial for Cryogenic ASU Training ?

Engineering-First Industrial Education & Consulting

Graphic Medium Industrial focuses on:

Cryogenic nitrogen and oxygen plants

Commissioning and stabilization workflows

Engineering documentation and toolkits

Knowledge systems for industrial teams

Our training is aligned with actual field workflows, not generic industrial theory.

Start Your Cryogenic ASU Learning Journey

Enroll in our Cryogenic ASU Training for Engineers and build strong foundation in commissioning, startup, and stable operation of air separation units.

Not ready to enroll yet? Start with our free cryogenic commissioning reference downloads to preview the learning style.

This training aligns with global process safety management principles for hazardous industrial systems.

Extend Learning With Practical Toolkits

Participants can also access:

Commissioning checklists

Trend interpretation guides

Troubleshooting flowcharts

Safety and compliance references

These tools help you apply training concepts directly to plant work.

Frequently Asked Questions

❓ Is this suitable for beginners?

Yes. This Cryogenic ASU Training for Engineers starts from basic principles and gradually builds toward plant systems and operations.

❓ Is this useful for working engineers?

Yes. This ASU commissioning and operations training focuses on real plant risks, stability issues, and troubleshooting mindset.

❓ Do you provide certificates?

Certificates of participation can be provided for training batches.

❓ Can this be arranged for company teams?

Yes. Customized corporate batches can be arranged with plant-specific focus.